- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

YFCT-12

YAFEI

YF140560

| Availability: | |

|---|---|

| Quantity: | |

In modern food packaging, the reliability of sealing equipment is critical to ensuring product integrity and preventing leaks or contamination. While many sealing systems rely on heat, there is a growing demand for efficient non-thermal sealing solutions. Yafei, a recognized manufacturer in packaging machinery components, offers a specialized Cup and Tray Sealing Blade designed for use in cold-sealing or pressure-sealing applications. This article provides a professional examination of this mechanical cutting tool

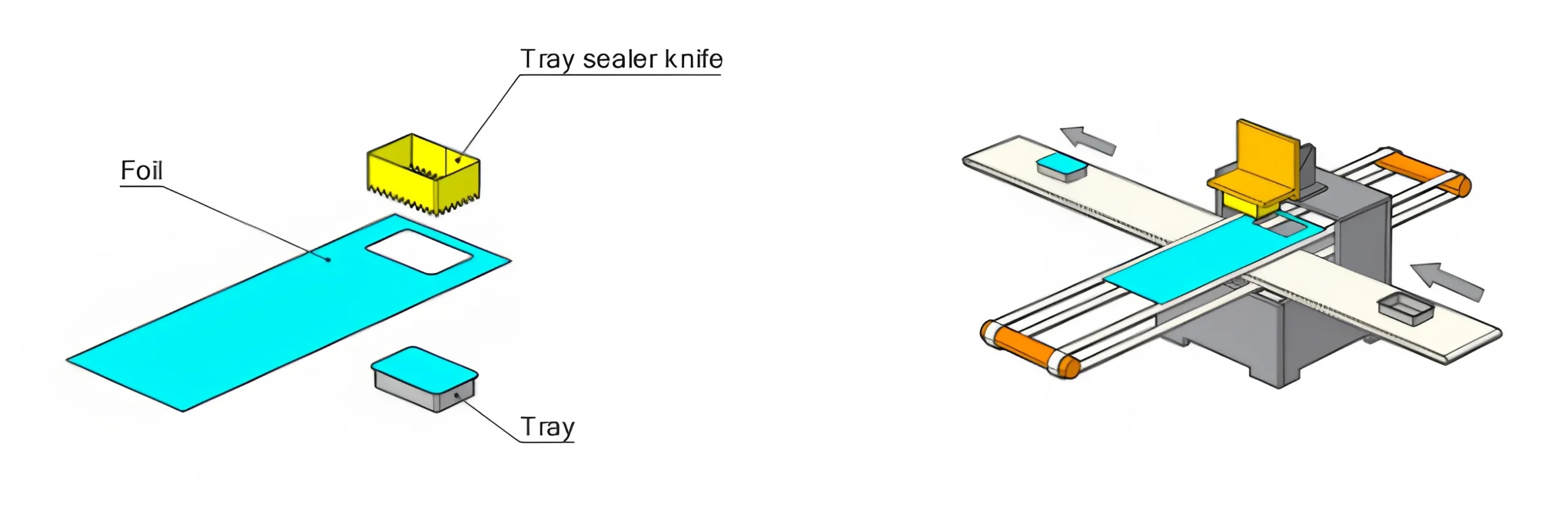

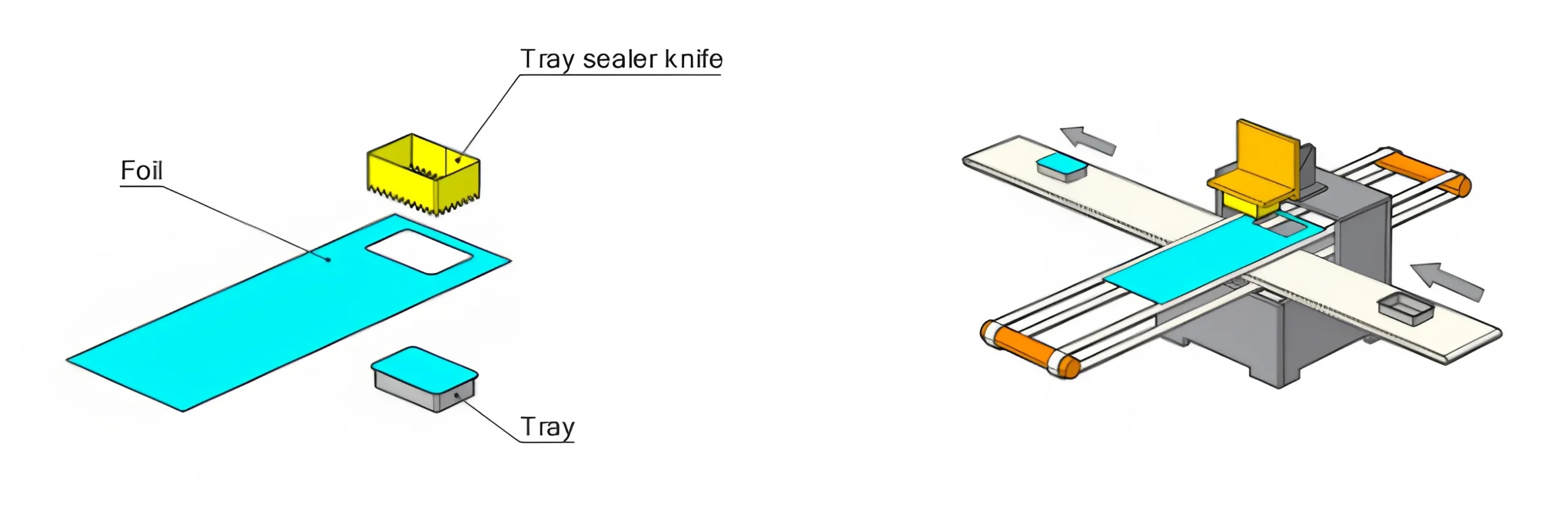

The Yafei Cup and Tray Sealing Blade is a precision-machined component used in sealing machines that utilize pressure-sensitive films or cold-seal adhesives. Unlike thermal knives, this blade operates without heating and performs two essential functions:

Cutting: The blade cleanly trims excess lidding material around the rim of the container.

Sealing Assistance: By applying uniform mechanical pressure, it ensures the adhesive layer of the film bonds completely and consistently to the container's flange.

This process creates a secure, leak-proof closure ideal for products sensitive to heat.

Yafei’s blade is engineered for durability, precision, and compatibility with non-thermal sealing systems:

Precision Machining: Manufactured from high-grade stainless steel or hardened alloys, the blade is machined to exact tolerances. Its cutting edge is sharp and durable, designed to provide a clean cut through various film materials without tearing.

Custom Contour Design: Each blade is custom-shaped to match the specific flange geometry of the container—whether for circular cups, rectangular trays, or custom-shaped bowls. This ensures a perfect trim and consistent seal around the entire perimeter.

Material Durability: Constructed to withstand continuous mechanical pressure and resist wear, the blade maintains its sharpness and structural integrity over long production runs, reducing downtime for maintenance or replacement.

Surface Finish: The contact surface is often polished to minimize friction and prevent film from sticking, facilitating smooth operation and easy cleaning, which is vital for maintaining hygiene standards.

Ease of Integration: Designed for compatibility with a range of mechanical and pneumatic sealing systems, Yafei’s blade serves as a reliable OEM replacement or upgrade part for cold-sealing machines.

This type of non-heated sealing blade is essential in industries where heat is unsuitable:

Fresh Produce & Salads: Sealing trays containing heat-sensitive fresh fruits, vegetables, and ready-to-eat salads.

Dairy Products: Sealing cups for fresh yogurt, cottage cheese, or other products where heat could affect texture or quality.

Chilled Desserts: Packaging of mousses, tiramisu, or other desserts that must remain refrigerated and untouched by heat.

Pharmaceutical & Healthcare: Sealing containers for diagnostic kits, medicated creams, or other sterile products where heat could compromise contents.

Product Integrity: Ideal for heat-sensitive products, preventing any risk of thermal damage, melting, or odor transfer.

Energy Efficiency: Operates without power-consuming heating elements, reducing energy costs.

Consistent Performance: Delivers reliable cutting and sealing performance unaffected by temperature fluctuations, ensuring uniform seal quality.

Low Maintenance: Without heating elements or associated wiring, the blade requires minimal upkeep beyond routine cleaning and occasional inspection.

Yafei Cup and Tray Sealing Blade is a precision mechanical component critical to non-thermal sealing processes. Its high-quality construction, custom design, and durable performance make it an essential tool for applications where heat is not an option. By ensuring clean cuts and supporting effective cold-seal adhesion, Yafei’s blade helps maintain product safety, quality, and appearance, making it a valuable component in advanced packaging lines focused on gentle and efficient sealing.

In modern food packaging, the reliability of sealing equipment is critical to ensuring product integrity and preventing leaks or contamination. While many sealing systems rely on heat, there is a growing demand for efficient non-thermal sealing solutions. Yafei, a recognized manufacturer in packaging machinery components, offers a specialized Cup and Tray Sealing Blade designed for use in cold-sealing or pressure-sealing applications. This article provides a professional examination of this mechanical cutting tool

The Yafei Cup and Tray Sealing Blade is a precision-machined component used in sealing machines that utilize pressure-sensitive films or cold-seal adhesives. Unlike thermal knives, this blade operates without heating and performs two essential functions:

Cutting: The blade cleanly trims excess lidding material around the rim of the container.

Sealing Assistance: By applying uniform mechanical pressure, it ensures the adhesive layer of the film bonds completely and consistently to the container's flange.

This process creates a secure, leak-proof closure ideal for products sensitive to heat.

Yafei’s blade is engineered for durability, precision, and compatibility with non-thermal sealing systems:

Precision Machining: Manufactured from high-grade stainless steel or hardened alloys, the blade is machined to exact tolerances. Its cutting edge is sharp and durable, designed to provide a clean cut through various film materials without tearing.

Custom Contour Design: Each blade is custom-shaped to match the specific flange geometry of the container—whether for circular cups, rectangular trays, or custom-shaped bowls. This ensures a perfect trim and consistent seal around the entire perimeter.

Material Durability: Constructed to withstand continuous mechanical pressure and resist wear, the blade maintains its sharpness and structural integrity over long production runs, reducing downtime for maintenance or replacement.

Surface Finish: The contact surface is often polished to minimize friction and prevent film from sticking, facilitating smooth operation and easy cleaning, which is vital for maintaining hygiene standards.

Ease of Integration: Designed for compatibility with a range of mechanical and pneumatic sealing systems, Yafei’s blade serves as a reliable OEM replacement or upgrade part for cold-sealing machines.

This type of non-heated sealing blade is essential in industries where heat is unsuitable:

Fresh Produce & Salads: Sealing trays containing heat-sensitive fresh fruits, vegetables, and ready-to-eat salads.

Dairy Products: Sealing cups for fresh yogurt, cottage cheese, or other products where heat could affect texture or quality.

Chilled Desserts: Packaging of mousses, tiramisu, or other desserts that must remain refrigerated and untouched by heat.

Pharmaceutical & Healthcare: Sealing containers for diagnostic kits, medicated creams, or other sterile products where heat could compromise contents.

Product Integrity: Ideal for heat-sensitive products, preventing any risk of thermal damage, melting, or odor transfer.

Energy Efficiency: Operates without power-consuming heating elements, reducing energy costs.

Consistent Performance: Delivers reliable cutting and sealing performance unaffected by temperature fluctuations, ensuring uniform seal quality.

Low Maintenance: Without heating elements or associated wiring, the blade requires minimal upkeep beyond routine cleaning and occasional inspection.

Yafei Cup and Tray Sealing Blade is a precision mechanical component critical to non-thermal sealing processes. Its high-quality construction, custom design, and durable performance make it an essential tool for applications where heat is not an option. By ensuring clean cuts and supporting effective cold-seal adhesion, Yafei’s blade helps maintain product safety, quality, and appearance, making it a valuable component in advanced packaging lines focused on gentle and efficient sealing.

content is empty!