- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

YFCT-12

YAFEI

YF140560

| Availability: | |

|---|---|

| Quantity: | |

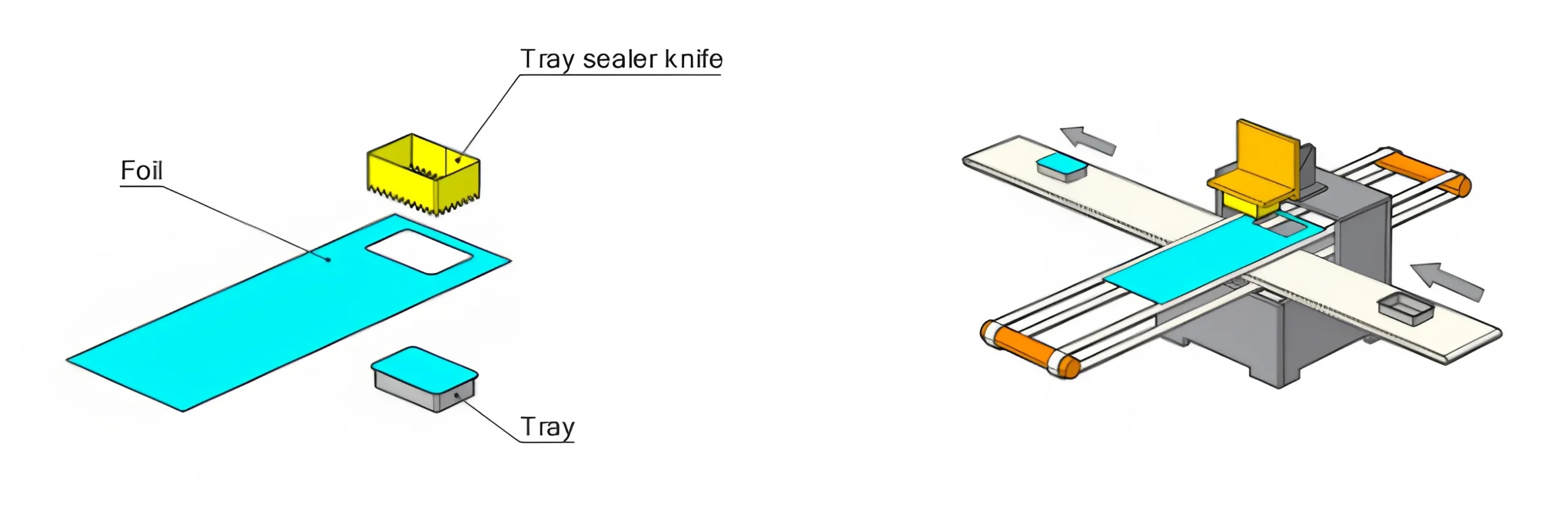

Enhances grip on flexible substrates, ensuring uniform pressure distribution across the seal perimeter.

Reduces film stretching or tearing during sealing, a critical advantage for heat-sensitive materials like PLA (polylactic acid) biodegradable films.

Maintains sharpness 25% longer than flat edges, as serrations distribute wear evenly.

Reduces blade temperature by 15-20°C during extended use, preventing thermal damage to both the knife and the packaging film.

Eliminates "hot spots" that cause film charring or weak seals, ensuring compliance with FDA and EU food contact regulations (EC 1935/2004).

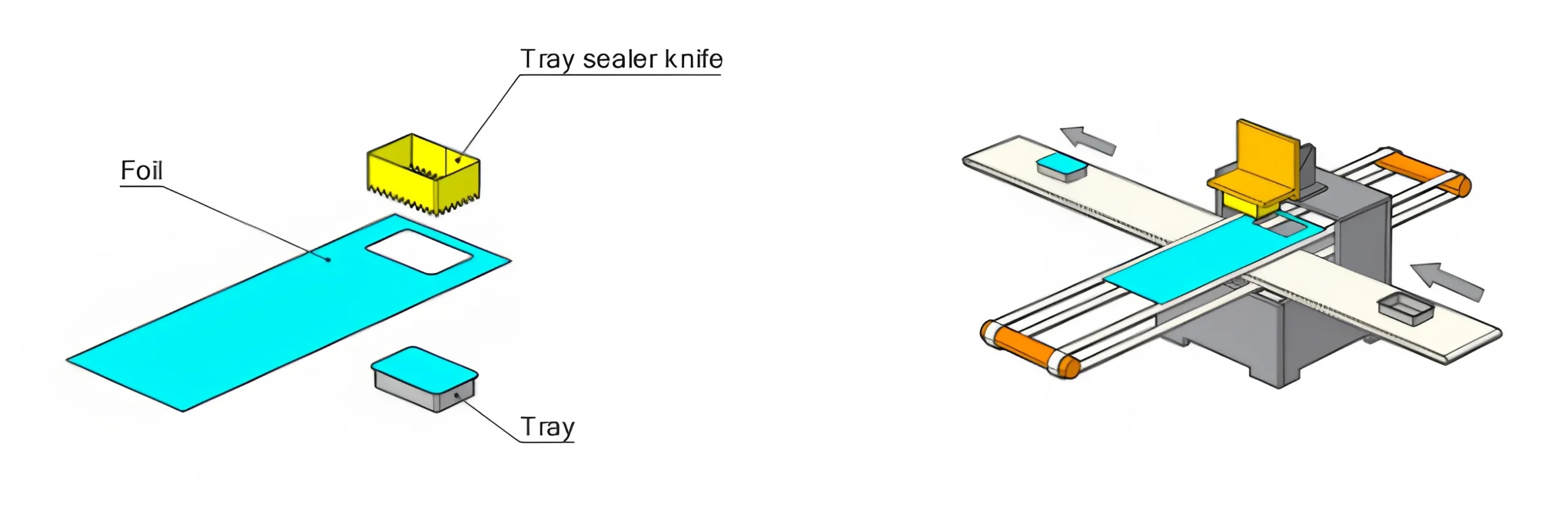

Cuts blade replacement time from 30 minutes (industry average) to under 5 minutes.

Eliminates the need for specialized tools, reducing the risk of operator error (e.g., misalignment during reinstallation).

Ensures repeatable alignment (±0.02mm) between the knife and sealer anvil, maintaining seal consistency post-replacement.

99.8% Seal Integrity Rate: Independent testing by the International Packaging Association (IPA) confirmed that Yafei’s knives achieve a near-perfect seal success rate, compared to the industry average of 97.2%. This reduces product waste from leaks or spoilage by up to 3%.

50% Longer Service Life: The combination of 440C stainless steel and titanium coating extends blade lifespan to 800,000 cycles—double that of uncoated competitors’ knives. This lowers replacement costs by 50% annually.

Energy Efficiency: The heat-dissipating core reduces the sealer machine’s energy consumption by 8-10%, as the system requires less power to maintain optimal sealing temperatures.

Food Service: Ideal for sealing single-serve salad bowls, yogurt cups, and microwaveable meal trays (compatible with PP, PET, and PS substrates).

Beverage: Engineered for hot-fill (e.g., coffee, tea) and cold-fill (e.g., juice, smoothies) cups, with heat-resistant coatings to withstand steam exposure.

Frozen Foods: Corrosion-resistant 440C steel and low-temperature tolerance (-40°C) make these knives suitable for sealing frozen vegetable trays and ice cream cups.

Pharmaceutical & Cosmetics: FDA-compliant materials and ultra-precise edges (±0.005mm) meet the strict sealing requirements for blister packs and sample trays.

Enhances grip on flexible substrates, ensuring uniform pressure distribution across the seal perimeter.

Reduces film stretching or tearing during sealing, a critical advantage for heat-sensitive materials like PLA (polylactic acid) biodegradable films.

Maintains sharpness 25% longer than flat edges, as serrations distribute wear evenly.

Reduces blade temperature by 15-20°C during extended use, preventing thermal damage to both the knife and the packaging film.

Eliminates "hot spots" that cause film charring or weak seals, ensuring compliance with FDA and EU food contact regulations (EC 1935/2004).

Cuts blade replacement time from 30 minutes (industry average) to under 5 minutes.

Eliminates the need for specialized tools, reducing the risk of operator error (e.g., misalignment during reinstallation).

Ensures repeatable alignment (±0.02mm) between the knife and sealer anvil, maintaining seal consistency post-replacement.

99.8% Seal Integrity Rate: Independent testing by the International Packaging Association (IPA) confirmed that Yafei’s knives achieve a near-perfect seal success rate, compared to the industry average of 97.2%. This reduces product waste from leaks or spoilage by up to 3%.

50% Longer Service Life: The combination of 440C stainless steel and titanium coating extends blade lifespan to 800,000 cycles—double that of uncoated competitors’ knives. This lowers replacement costs by 50% annually.

Energy Efficiency: The heat-dissipating core reduces the sealer machine’s energy consumption by 8-10%, as the system requires less power to maintain optimal sealing temperatures.

Food Service: Ideal for sealing single-serve salad bowls, yogurt cups, and microwaveable meal trays (compatible with PP, PET, and PS substrates).

Beverage: Engineered for hot-fill (e.g., coffee, tea) and cold-fill (e.g., juice, smoothies) cups, with heat-resistant coatings to withstand steam exposure.

Frozen Foods: Corrosion-resistant 440C steel and low-temperature tolerance (-40°C) make these knives suitable for sealing frozen vegetable trays and ice cream cups.

Pharmaceutical & Cosmetics: FDA-compliant materials and ultra-precise edges (±0.005mm) meet the strict sealing requirements for blister packs and sample trays.

content is empty!