- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

YFCT-12

YAFEI

YF140560

| Availability: | |

|---|---|

| Quantity: | |

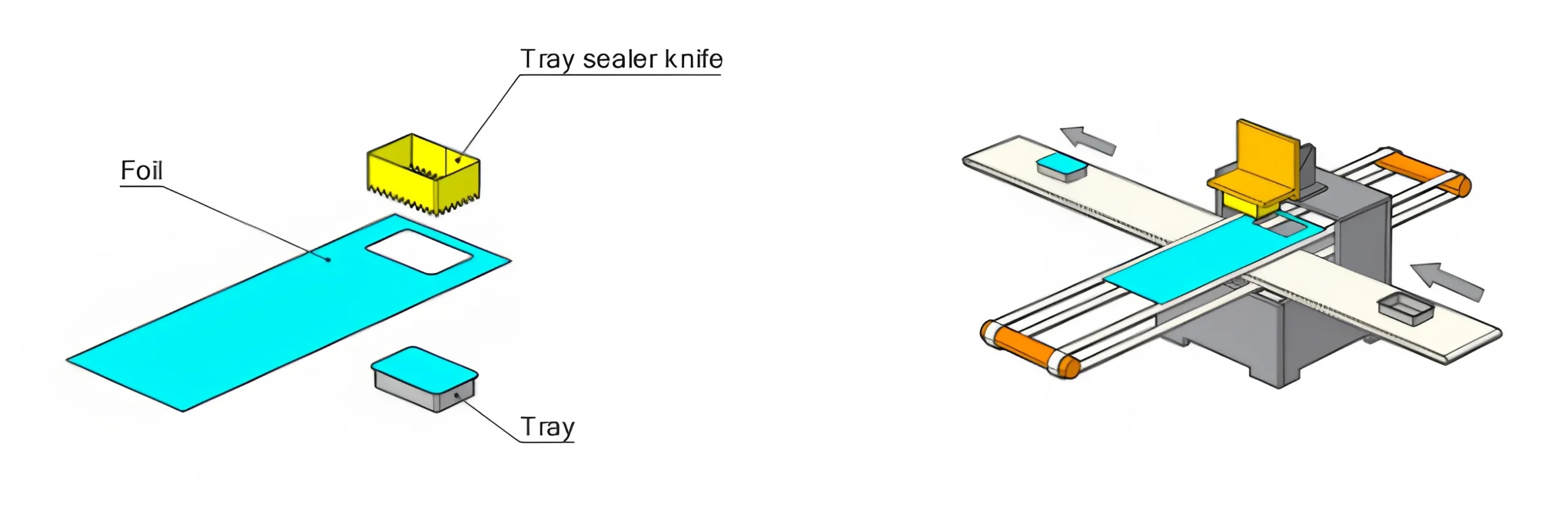

Material Engineering: Typically crafted from premium stainless steel (304/316/420) or heat-resistant alloys, ensuring corrosion resistance (critical for F&B/pharma compliance) and dimensional stability at 120–250°C (adjustable by application). Specialized versions may have Teflon® coatings to prevent film adhesion, ideal for ultra-thin films or high-fat products.

Structural Precision: Machined to ±0.01mm tolerances, the blade’s edge ensures uniform pressure across container flanges—eliminating leak-causing "cold spots" or film-damaging "overheating". Modular designs enable quick adaptation to 50ml–2L container sizes without full component replacement.

Thermal Control: Integrated with cartridge heaters and PT100 thermistors for closed-loop temperature regulation, maintaining constant heat even at high speeds (up to 60 cycles/min). Essential for sealing multi-layer films (PE/PP laminates, aluminum foil, oxygen/moisture barrier films).

Hermetic Reliability: Creates a tight flange-film bond to block oxygen, moisture, and contaminants, extending shelf life by 2–5x—vital for perishables and sterile medical products.

High-Speed Durability: Supports 24/7 operation with 3,000–8,000 hours of service intervals (depending on usage), minimizing unplanned downtime.

Compliance & Safety: Meets global standards (FDA for food contact, EU 10/2011 for plastics, ISO 13485 for medical devices). Crevice-free surfaces reduce residue buildup, simplifying cleaning and cross-contamination prevention.

Dairy Sector: Used in automated lines for 200ml–500ml yogurt cups. The blade’s precise thermal control seals PE/Aluminum laminate films without overheating, preserving yogurt’s probiotic activity while extending shelf life to 21 days (vs. 7 days for non-hermetic seals).

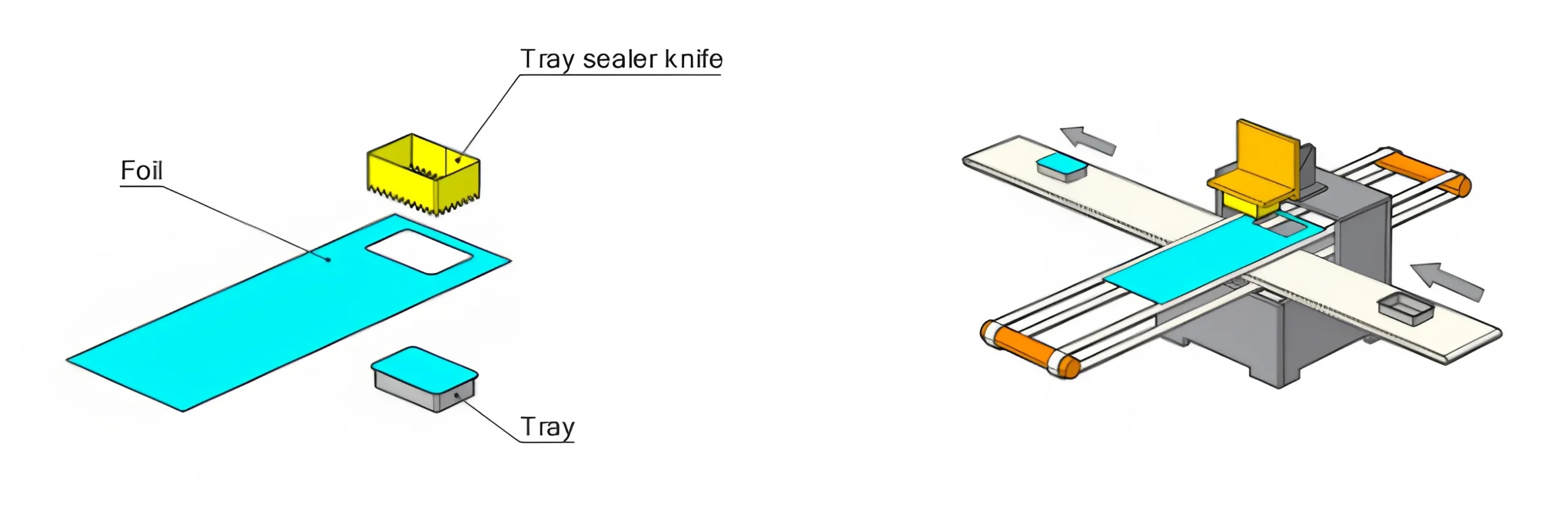

Ready-to-Eat (RTE) Meals: Applied to 300g–500g plastic trays for frozen or chilled meals (e.g., pasta, grilled chicken). Its corrosion-resistant stainless steel construction withstands frequent cleaning with food-grade solvents, ensuring compliance with HACCP standards.

Beverage Cups: Integral to sealing 350ml–1L cold coffee or juice cups. Teflon-coated blades prevent sticky syrup or cream residues from adhering, reducing maintenance stops by 40% in high-volume convenience store lines.

Blister Packs for Tablets/Capsules: The blade’s micro-tolerance machining (±0.01mm) ensures uniform seals on PVC/Aluminum blister trays, preventing moisture ingress that could degrade drug potency. It meets ISO 13485 requirements for sterile medical packaging.

Medical Device Trays: Used to seal trays holding disposable syringes or surgical gauze. Its hermetic sealing blocks microbial contamination, maintaining sterility until the tray is opened in clinical settings.

Cream Jars & Sample Trays: Seals 10ml–50ml plastic jars for face creams or 5ml sample trays for serums. The blade’s adjustable temperature (150–180°C) works with thin PET films, avoiding film warping while ensuring a tamper-evident seal—critical for consumer trust.

Routine cleaning with food/medical-grade solvents to remove film or product residue.

Periodic calibration of thermal sensors to sustain consistent heat output.

Cost-efficient replacement of worn edges (instead of full components) for high-volume applications, reducing total ownership cost.

Material Engineering: Typically crafted from premium stainless steel (304/316/420) or heat-resistant alloys, ensuring corrosion resistance (critical for F&B/pharma compliance) and dimensional stability at 120–250°C (adjustable by application). Specialized versions may have Teflon® coatings to prevent film adhesion, ideal for ultra-thin films or high-fat products.

Structural Precision: Machined to ±0.01mm tolerances, the blade’s edge ensures uniform pressure across container flanges—eliminating leak-causing "cold spots" or film-damaging "overheating". Modular designs enable quick adaptation to 50ml–2L container sizes without full component replacement.

Thermal Control: Integrated with cartridge heaters and PT100 thermistors for closed-loop temperature regulation, maintaining constant heat even at high speeds (up to 60 cycles/min). Essential for sealing multi-layer films (PE/PP laminates, aluminum foil, oxygen/moisture barrier films).

Hermetic Reliability: Creates a tight flange-film bond to block oxygen, moisture, and contaminants, extending shelf life by 2–5x—vital for perishables and sterile medical products.

High-Speed Durability: Supports 24/7 operation with 3,000–8,000 hours of service intervals (depending on usage), minimizing unplanned downtime.

Compliance & Safety: Meets global standards (FDA for food contact, EU 10/2011 for plastics, ISO 13485 for medical devices). Crevice-free surfaces reduce residue buildup, simplifying cleaning and cross-contamination prevention.

Dairy Sector: Used in automated lines for 200ml–500ml yogurt cups. The blade’s precise thermal control seals PE/Aluminum laminate films without overheating, preserving yogurt’s probiotic activity while extending shelf life to 21 days (vs. 7 days for non-hermetic seals).

Ready-to-Eat (RTE) Meals: Applied to 300g–500g plastic trays for frozen or chilled meals (e.g., pasta, grilled chicken). Its corrosion-resistant stainless steel construction withstands frequent cleaning with food-grade solvents, ensuring compliance with HACCP standards.

Beverage Cups: Integral to sealing 350ml–1L cold coffee or juice cups. Teflon-coated blades prevent sticky syrup or cream residues from adhering, reducing maintenance stops by 40% in high-volume convenience store lines.

Blister Packs for Tablets/Capsules: The blade’s micro-tolerance machining (±0.01mm) ensures uniform seals on PVC/Aluminum blister trays, preventing moisture ingress that could degrade drug potency. It meets ISO 13485 requirements for sterile medical packaging.

Medical Device Trays: Used to seal trays holding disposable syringes or surgical gauze. Its hermetic sealing blocks microbial contamination, maintaining sterility until the tray is opened in clinical settings.

Cream Jars & Sample Trays: Seals 10ml–50ml plastic jars for face creams or 5ml sample trays for serums. The blade’s adjustable temperature (150–180°C) works with thin PET films, avoiding film warping while ensuring a tamper-evident seal—critical for consumer trust.

Routine cleaning with food/medical-grade solvents to remove film or product residue.

Periodic calibration of thermal sensors to sustain consistent heat output.

Cost-efficient replacement of worn edges (instead of full components) for high-volume applications, reducing total ownership cost.

content is empty!