- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

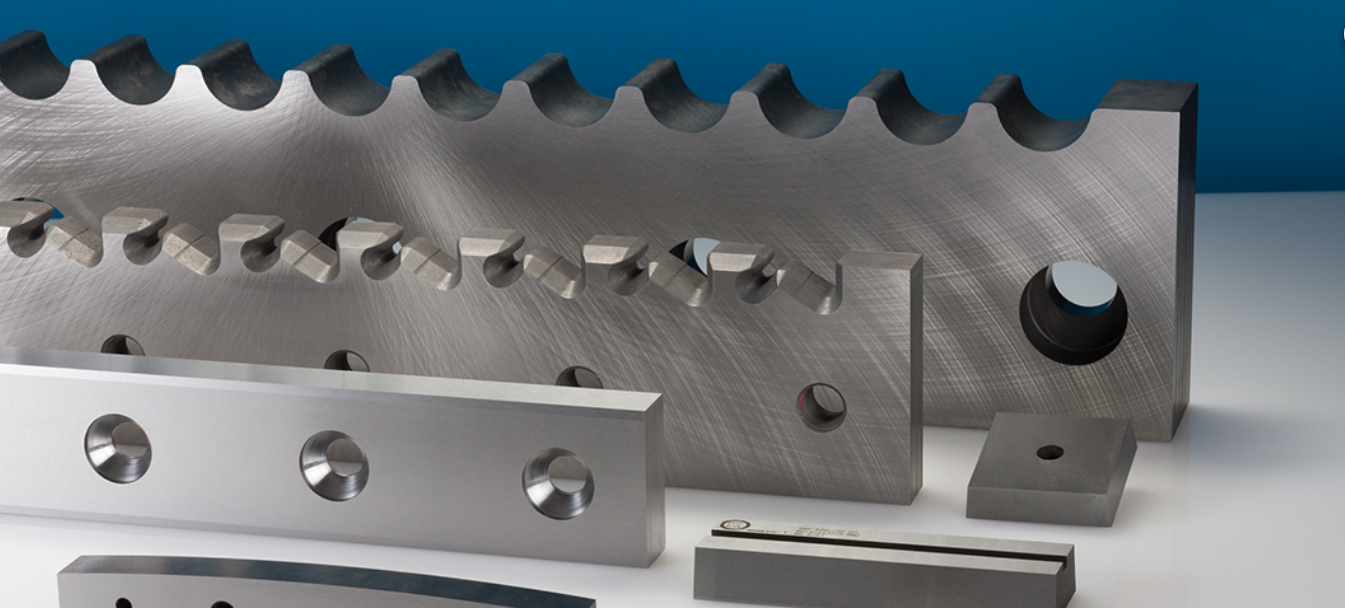

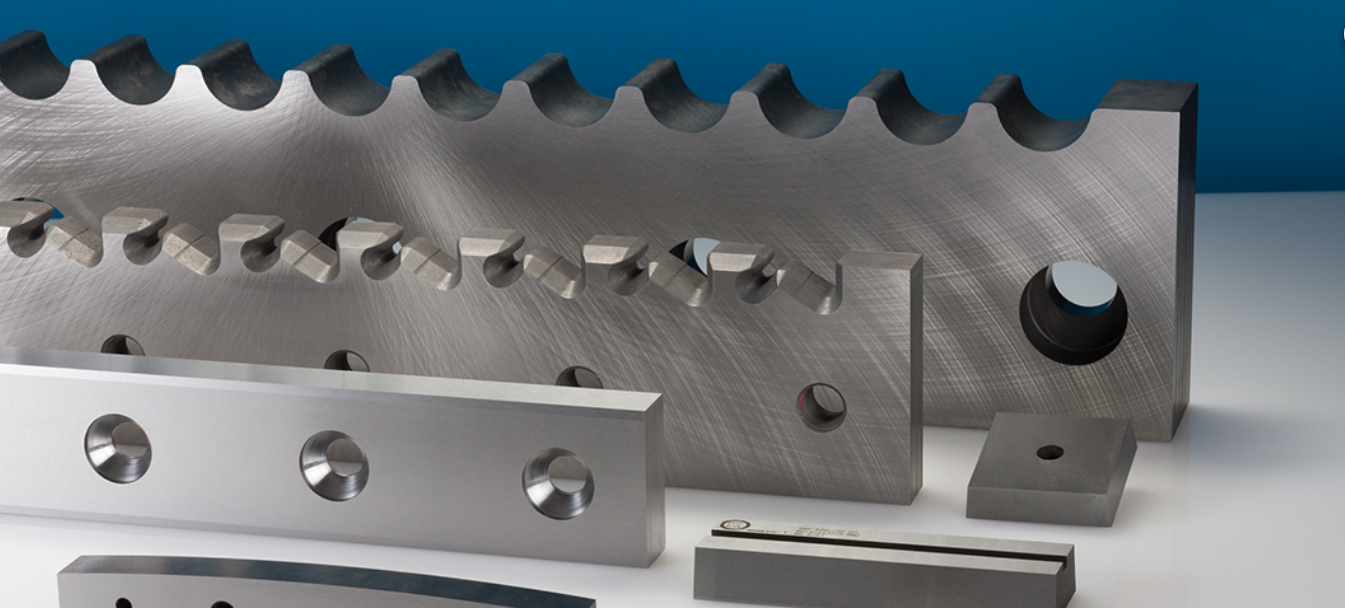

Whether you call them shears, slitters, cutters, blades, or knives, we understand the metal processing industry and your needs. Yafei blades has 30+ years of metallurgical and field experience to match the right tooling specifications to your application. We produce knives for brands such as: Siemens VAI, SMS Siemag AG, Danieli, Fimi, CMI FPE, BWG, and others. Our knives are made from material which is high wear resistant and has good tensile strength, combined with the most suitable heat treatment for optimum wear resistance and toughness for a longer life.

| Availability: | |

|---|---|

| Quantity: | |

YAFEI’s Hydraulic Shear Machine Blade is a heavy-duty tool for the metal processing industry, engineered to withstand the intense pressure of hydraulic shear machines—equipment used for cutting thick or tough metal materials. Unlike standard shear blades, which often bend or crack under hydraulic force, YAFEI’s blade uses premium materials and optimized heat treatment to deliver strength, durability, and precision. With over three decades of experience in metal processing tools, YAFEI’s blade fits leading hydraulic shear brands, making it a reliable choice for heavy industries like shipbuilding, construction, and automotive manufacturing.

Hydraulic shears are renowned for their ability to exert an enormous amount of pressure. YAFEI's hydraulic shears, in particular, stand out due to their blade construction. The blade is crafted from high-tensile-strength alloys, which endow it with remarkable properties. These alloys are designed to withstand the intense forces generated during the cutting process. Even when tasked with cutting through thick metal plates or sturdy metal bars, the blade resists bending, cracking, or undergoing any form of deformation. This ensures consistent and precise cutting performance, making YAFEI's hydraulic shears a reliable choice for various metalworking applications.

A meticulously tailored custom heat treatment process is employed to ensure that the blade of the hydraulic shears attains an optimal combination of two crucial properties. Firstly, it is made tough enough to effectively absorb impact. This is essential as the shears are frequently subjected to forces generated during the cutting operation, and the blade needs to withstand these impacts without fracturing or deforming. Secondly, the blade is rendered wear - resistant, enabling it to handle repeated cutting actions with ease. This property is vital because hydraulic shears are typically used to cut a diverse mix of metal types, and continuous cutting can cause significant wear and tear on the blade. Achieving the right balance between toughness and wear - resistance is of utmost criticality for hydraulic shears. Their functionality depends on this delicate equilibrium, as they need to perform consistently and efficiently when dealing with different metals in various cutting tasks.

The blade’s edge is ground to a precise angle that ensures clean, straight cuts on thick metals. This reduces material waste and eliminates the need for secondary grinding—saving time in heavy fabrication.

The blade serves a crucial function in hydraulic shear machines. These machines are widely employed to cut through thick metal sheets, plates, or bars. This application is prevalent across several key industries. In the construction sector, for instance, it is commonly used when working with structural steel, which forms the backbone of buildings and other structures. In shipbuilding, the hydraulic shear machines equipped with these blades play a vital role in cutting materials for hull components, ensuring the precise shaping of the ship's body. Similarly, in heavy equipment manufacturing, they are utilized for cutting materials to create machine frames, which are essential for the stability and functionality of heavy machinery.

In scrap yards, the blade is specifically designed to be a perfect fit for hydraulic scrap shears. These hydraulic scrap shears play a crucial role in the recycling process. Their main function is to cut large metal scrap items. Such items can range from old cars, which are no longer in use and need to be recycled to recover valuable metals, to industrial machinery that has reached the end of its operational life. Steel beams, often used in construction projects, are also among the types of large metal scrap that the hydraulic scrap shears handle. By cutting these large metal pieces into smaller, more manageable chunks, it becomes easier to transport them to recycling facilities or other appropriate destinations for further processing. This ensures a more efficient recycling and waste - management system within the scrap yard environment.

For general metal fabrication purposes, the blade plays a crucial role in cutting metal. It is specifically utilized to transform metal into preliminary shapes that are destined for large components. These large components include elements like crane parts, which need to be incredibly strong to withstand the heavy loads during lifting operations. Truck frames are another example, where both strength to support the vehicle's weight and the cargo it carries, as well as precision in manufacturing to ensure proper fitting of various parts, are of utmost importance. Industrial valves also fall into this category, as they require a high level of strength to handle the pressures and flows within industrial systems, and precision in their shape is essential for accurate operation and control. The blade is thus integral in shaping metal for these large components where strength and precision are absolutely essential aspects of their functionality.

It handles a wide range of thicknesses, from medium-gauge sheets to thick plates. For extremely thick metals (e.g., over 50mm), YAFEI can recommend a specialized blade material to maintain performance.

YAFEI’s blades fit most leading hydraulic shear brands, including Siemens VAI and Danieli. For custom or older machines, provide your machine’s specifications, and we’ll design a blade that fits perfectly.

Signs include: increased cutting force required, uneven or jagged cuts, visible chips or cracks on the edge, or vibration during cutting. Replace the blade immediately if cracks are present—they can spread and cause machine damage.

Clean the blade after use to remove metal shavings. Ensure it’s properly aligned in the shear machine (misalignment causes uneven wear). Avoid cutting materials harder than the blade’s capacity (e.g., hardened steel) unless using a specialized blade.

YAFEI’s Hydraulic Shear Machine Blade is a heavy-duty tool for the metal processing industry, engineered to withstand the intense pressure of hydraulic shear machines—equipment used for cutting thick or tough metal materials. Unlike standard shear blades, which often bend or crack under hydraulic force, YAFEI’s blade uses premium materials and optimized heat treatment to deliver strength, durability, and precision. With over three decades of experience in metal processing tools, YAFEI’s blade fits leading hydraulic shear brands, making it a reliable choice for heavy industries like shipbuilding, construction, and automotive manufacturing.

Hydraulic shears are renowned for their ability to exert an enormous amount of pressure. YAFEI's hydraulic shears, in particular, stand out due to their blade construction. The blade is crafted from high-tensile-strength alloys, which endow it with remarkable properties. These alloys are designed to withstand the intense forces generated during the cutting process. Even when tasked with cutting through thick metal plates or sturdy metal bars, the blade resists bending, cracking, or undergoing any form of deformation. This ensures consistent and precise cutting performance, making YAFEI's hydraulic shears a reliable choice for various metalworking applications.

A meticulously tailored custom heat treatment process is employed to ensure that the blade of the hydraulic shears attains an optimal combination of two crucial properties. Firstly, it is made tough enough to effectively absorb impact. This is essential as the shears are frequently subjected to forces generated during the cutting operation, and the blade needs to withstand these impacts without fracturing or deforming. Secondly, the blade is rendered wear - resistant, enabling it to handle repeated cutting actions with ease. This property is vital because hydraulic shears are typically used to cut a diverse mix of metal types, and continuous cutting can cause significant wear and tear on the blade. Achieving the right balance between toughness and wear - resistance is of utmost criticality for hydraulic shears. Their functionality depends on this delicate equilibrium, as they need to perform consistently and efficiently when dealing with different metals in various cutting tasks.

The blade’s edge is ground to a precise angle that ensures clean, straight cuts on thick metals. This reduces material waste and eliminates the need for secondary grinding—saving time in heavy fabrication.

The blade serves a crucial function in hydraulic shear machines. These machines are widely employed to cut through thick metal sheets, plates, or bars. This application is prevalent across several key industries. In the construction sector, for instance, it is commonly used when working with structural steel, which forms the backbone of buildings and other structures. In shipbuilding, the hydraulic shear machines equipped with these blades play a vital role in cutting materials for hull components, ensuring the precise shaping of the ship's body. Similarly, in heavy equipment manufacturing, they are utilized for cutting materials to create machine frames, which are essential for the stability and functionality of heavy machinery.

In scrap yards, the blade is specifically designed to be a perfect fit for hydraulic scrap shears. These hydraulic scrap shears play a crucial role in the recycling process. Their main function is to cut large metal scrap items. Such items can range from old cars, which are no longer in use and need to be recycled to recover valuable metals, to industrial machinery that has reached the end of its operational life. Steel beams, often used in construction projects, are also among the types of large metal scrap that the hydraulic scrap shears handle. By cutting these large metal pieces into smaller, more manageable chunks, it becomes easier to transport them to recycling facilities or other appropriate destinations for further processing. This ensures a more efficient recycling and waste - management system within the scrap yard environment.

For general metal fabrication purposes, the blade plays a crucial role in cutting metal. It is specifically utilized to transform metal into preliminary shapes that are destined for large components. These large components include elements like crane parts, which need to be incredibly strong to withstand the heavy loads during lifting operations. Truck frames are another example, where both strength to support the vehicle's weight and the cargo it carries, as well as precision in manufacturing to ensure proper fitting of various parts, are of utmost importance. Industrial valves also fall into this category, as they require a high level of strength to handle the pressures and flows within industrial systems, and precision in their shape is essential for accurate operation and control. The blade is thus integral in shaping metal for these large components where strength and precision are absolutely essential aspects of their functionality.

It handles a wide range of thicknesses, from medium-gauge sheets to thick plates. For extremely thick metals (e.g., over 50mm), YAFEI can recommend a specialized blade material to maintain performance.

YAFEI’s blades fit most leading hydraulic shear brands, including Siemens VAI and Danieli. For custom or older machines, provide your machine’s specifications, and we’ll design a blade that fits perfectly.

Signs include: increased cutting force required, uneven or jagged cuts, visible chips or cracks on the edge, or vibration during cutting. Replace the blade immediately if cracks are present—they can spread and cause machine damage.

Clean the blade after use to remove metal shavings. Ensure it’s properly aligned in the shear machine (misalignment causes uneven wear). Avoid cutting materials harder than the blade’s capacity (e.g., hardened steel) unless using a specialized blade.