- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

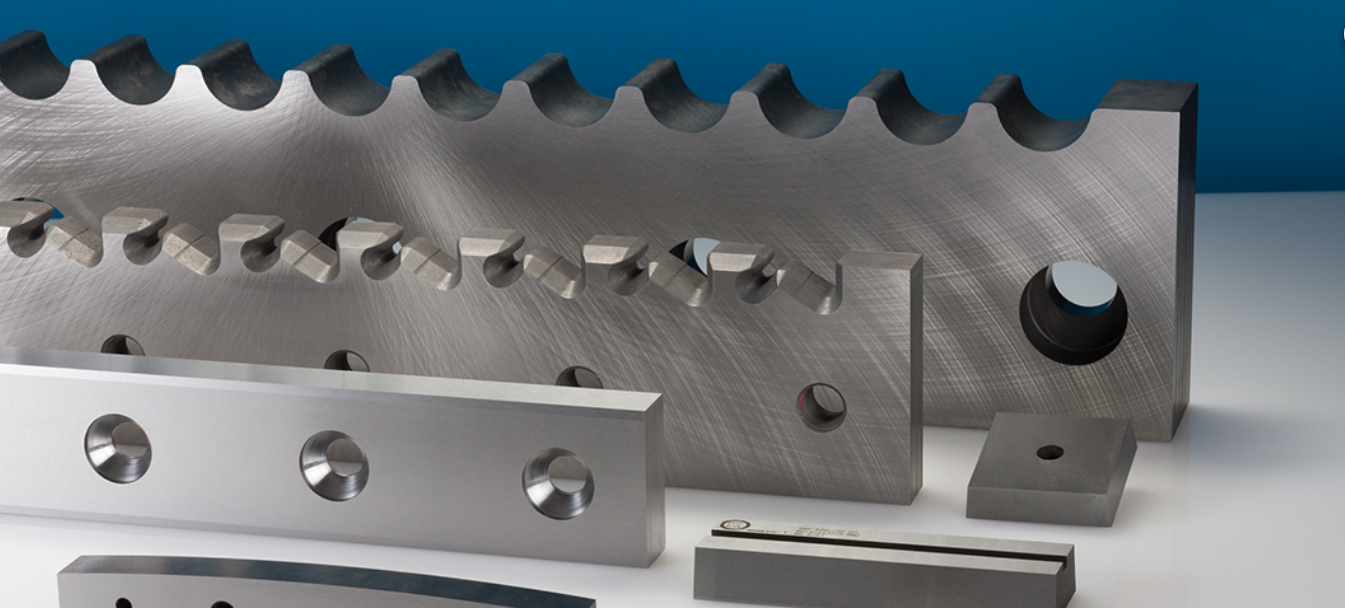

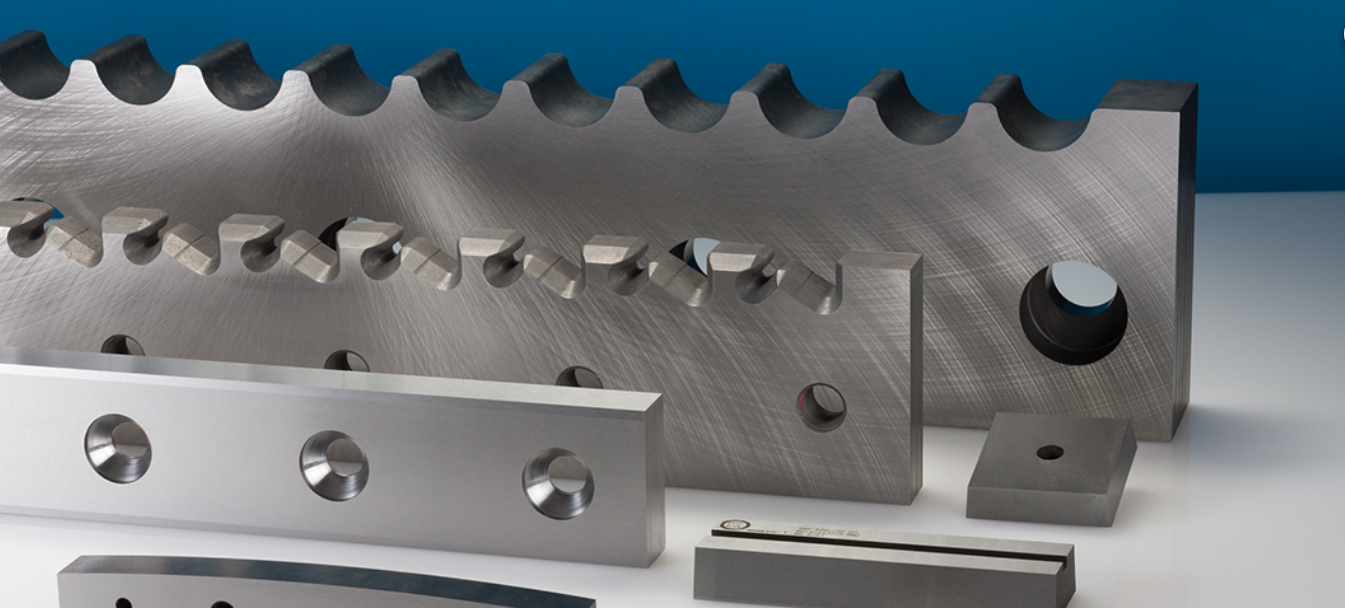

Whether you call them shears, slitters, cutters, blades, or knives, we understand the metal processing industry and your needs. Yafei blades has 30+ years of metallurgical and field experience to match the right tooling specifications to your application. We produce knives for brands such as: Siemens VAI, SMS Siemag AG, Danieli, Fimi, CMI FPE, BWG, and others. Our knives are made from material which is high wear resistant and has good tensile strength, combined with the most suitable heat treatment for optimum wear resistance and toughness for a longer life.

| Availability: | |

|---|---|

| Quantity: | |

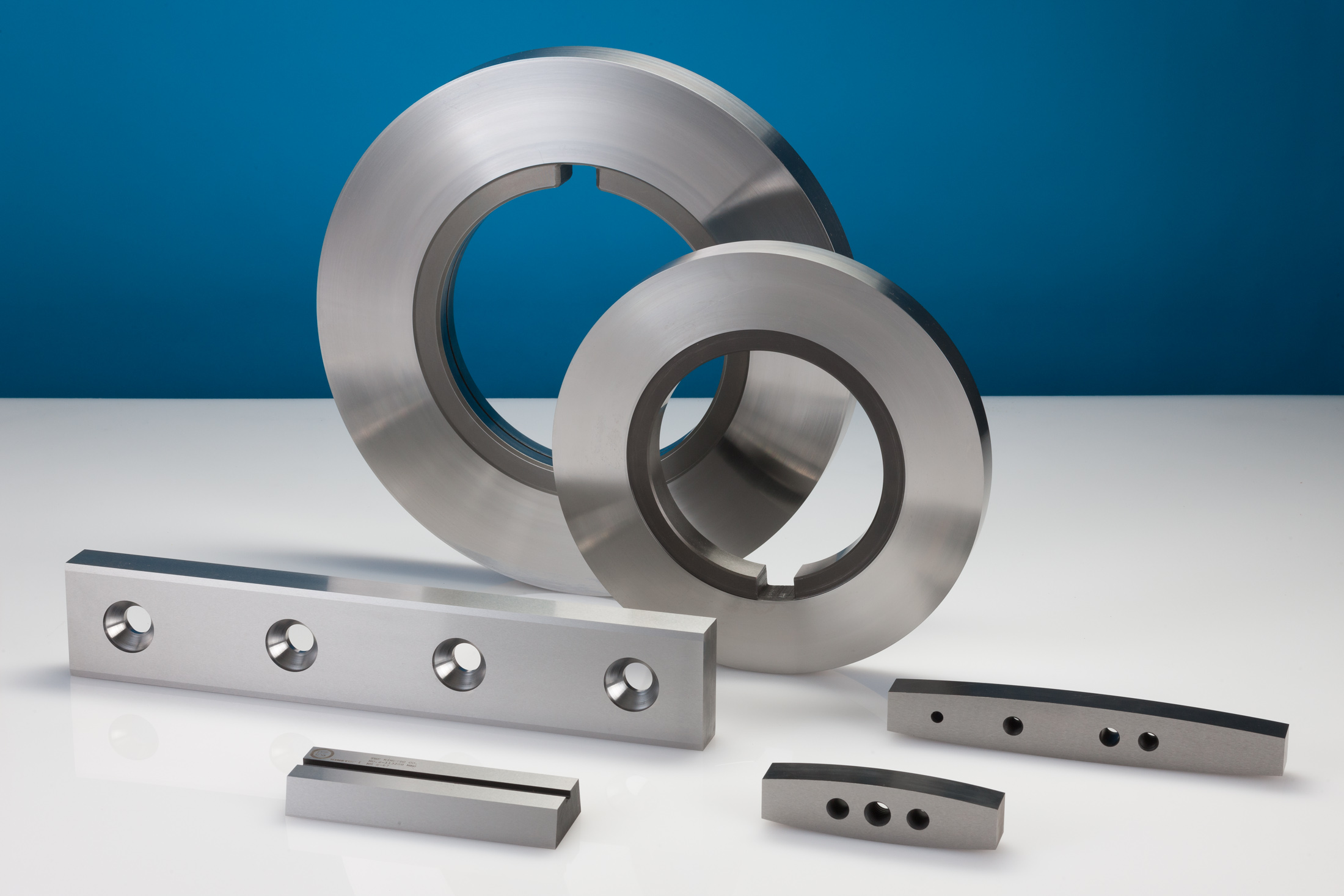

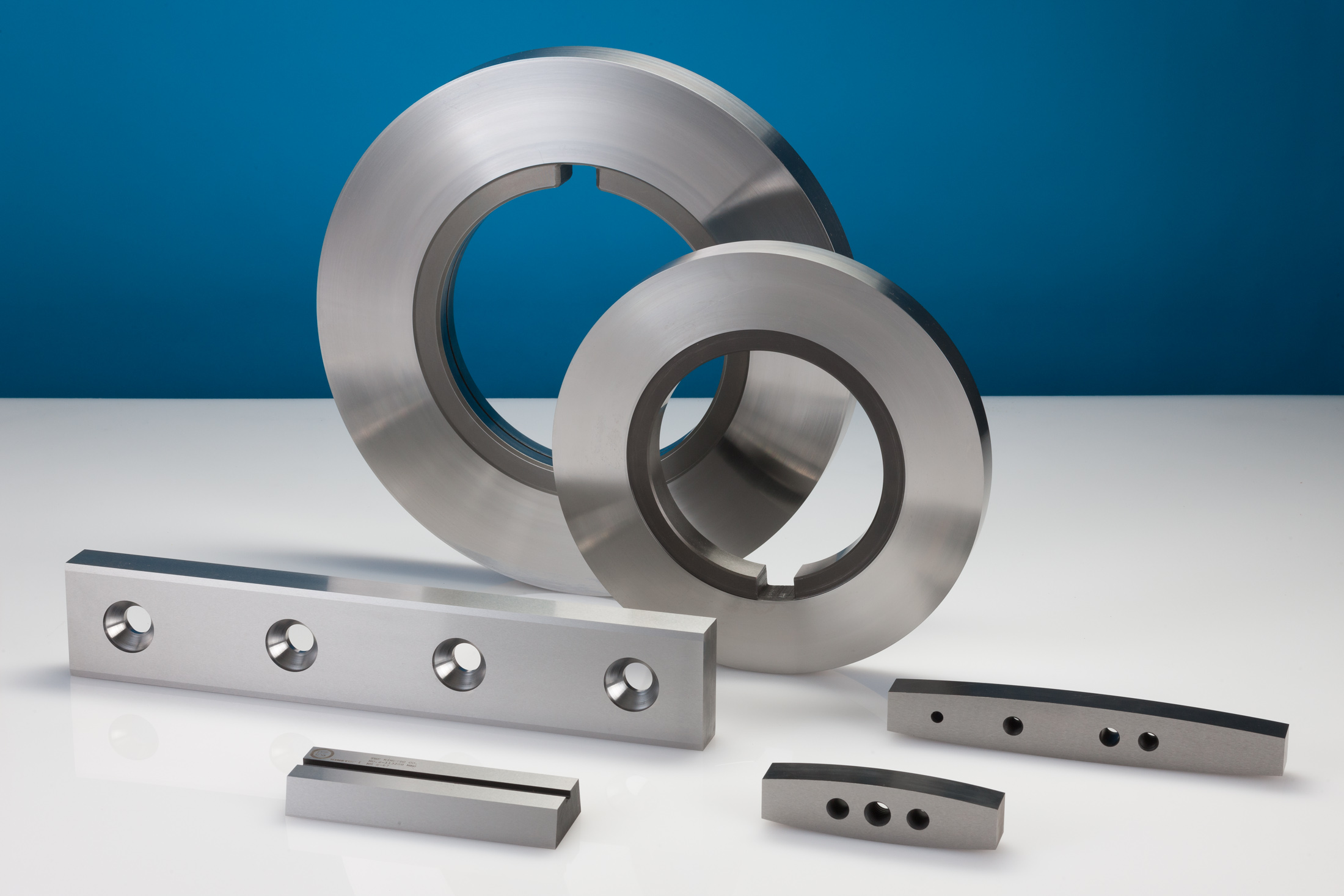

YAFEI’s Silicon Steel Sheet Tungsten Carbide Rotary Slitting Knife is a high-performance tool for processing silicon steel sheets— a critical material in electrical and electronic industries (used in transformers, motors, and inductors). Silicon steel’s unique properties (abrasive, magnetically sensitive) require a specialized blade, and YAFEI delivers this with tungsten carbide— a material renowned for hardness and wear resistance— paired with precision engineering. This knife ensures ultra-precise slitting, minimal edge damage, and long service life, meeting the strict quality standards of electrical component manufacturing.

Tungsten carbide is significantly harder than steel, making it ideal for slitting abrasive silicon steel sheets. It maintains sharpness far longer than standard blades, reducing the need for frequent replacement.

The rotary design ensures even pressure across the silicon steel sheet, preventing edge burrs or deformation. This is critical for electrical components—burrs can cause short circuits or reduce magnetic efficiency.

Slitting silicon steel generates localized heat, which can warp standard blades. Tungsten carbide resists thermal expansion, maintaining cutting accuracy even during prolonged operation.

In transformer production, the knife slits silicon steel sheets into strips used to make transformer cores. Precise slitting ensures the core has minimal energy loss, a key factor in efficient transformers.

For motor stators and rotors (used in cars, appliances, and industrial machines), the knife slits silicon steel into precise widths. This ensures the motor has optimal magnetic performance and energy efficiency.

In electronics, the knife slits thin silicon steel sheets into small strips for inductors, chokes, and magnetic cores. The minimal edge damage preserves the component’s electrical properties.

Silicon steel is abrasive and requires a blade that won’t dull quickly. Tungsten carbide’s hardness (up to 90 HRA) resists wear, ensuring consistent precision. Steel blades would dull within hours of slitting silicon steel, causing poor quality and downtime.

Yes. YAFEI offers custom designs based on your sheet’s thickness, width, and desired slit strip dimensions. We also adjust the knife to fit your slitting machine’s specifications.

Tungsten carbide is hard but brittle—avoid dropping or impacting the knife. Store it in a dry, padded container to prevent chips. When installing, use gentle pressure to avoid cracking.

Yes. Tungsten carbide requires specialized sharpening equipment, and YAFEI provides professional sharpening services to restore the knife’s performance. We recommend sharpening when slitting accuracy drops or burrs appear.

YAFEI’s Silicon Steel Sheet Tungsten Carbide Rotary Slitting Knife is a high-performance tool for processing silicon steel sheets— a critical material in electrical and electronic industries (used in transformers, motors, and inductors). Silicon steel’s unique properties (abrasive, magnetically sensitive) require a specialized blade, and YAFEI delivers this with tungsten carbide— a material renowned for hardness and wear resistance— paired with precision engineering. This knife ensures ultra-precise slitting, minimal edge damage, and long service life, meeting the strict quality standards of electrical component manufacturing.

Tungsten carbide is significantly harder than steel, making it ideal for slitting abrasive silicon steel sheets. It maintains sharpness far longer than standard blades, reducing the need for frequent replacement.

The rotary design ensures even pressure across the silicon steel sheet, preventing edge burrs or deformation. This is critical for electrical components—burrs can cause short circuits or reduce magnetic efficiency.

Slitting silicon steel generates localized heat, which can warp standard blades. Tungsten carbide resists thermal expansion, maintaining cutting accuracy even during prolonged operation.

In transformer production, the knife slits silicon steel sheets into strips used to make transformer cores. Precise slitting ensures the core has minimal energy loss, a key factor in efficient transformers.

For motor stators and rotors (used in cars, appliances, and industrial machines), the knife slits silicon steel into precise widths. This ensures the motor has optimal magnetic performance and energy efficiency.

In electronics, the knife slits thin silicon steel sheets into small strips for inductors, chokes, and magnetic cores. The minimal edge damage preserves the component’s electrical properties.

Silicon steel is abrasive and requires a blade that won’t dull quickly. Tungsten carbide’s hardness (up to 90 HRA) resists wear, ensuring consistent precision. Steel blades would dull within hours of slitting silicon steel, causing poor quality and downtime.

Yes. YAFEI offers custom designs based on your sheet’s thickness, width, and desired slit strip dimensions. We also adjust the knife to fit your slitting machine’s specifications.

Tungsten carbide is hard but brittle—avoid dropping or impacting the knife. Store it in a dry, padded container to prevent chips. When installing, use gentle pressure to avoid cracking.

Yes. Tungsten carbide requires specialized sharpening equipment, and YAFEI provides professional sharpening services to restore the knife’s performance. We recommend sharpening when slitting accuracy drops or burrs appear.