- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

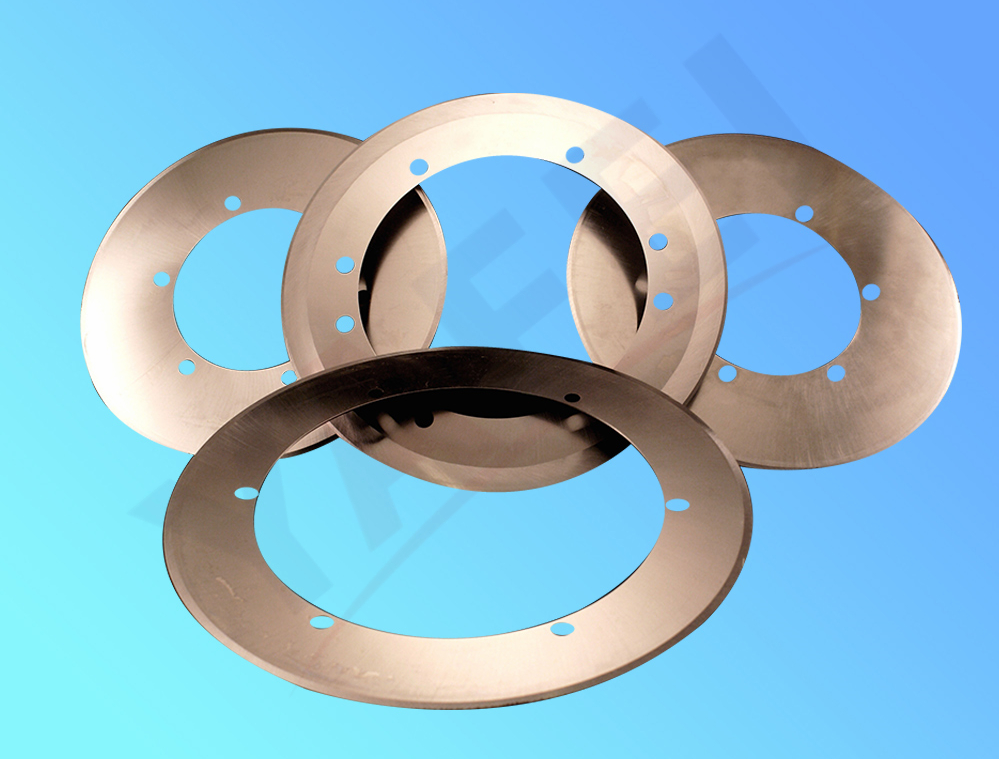

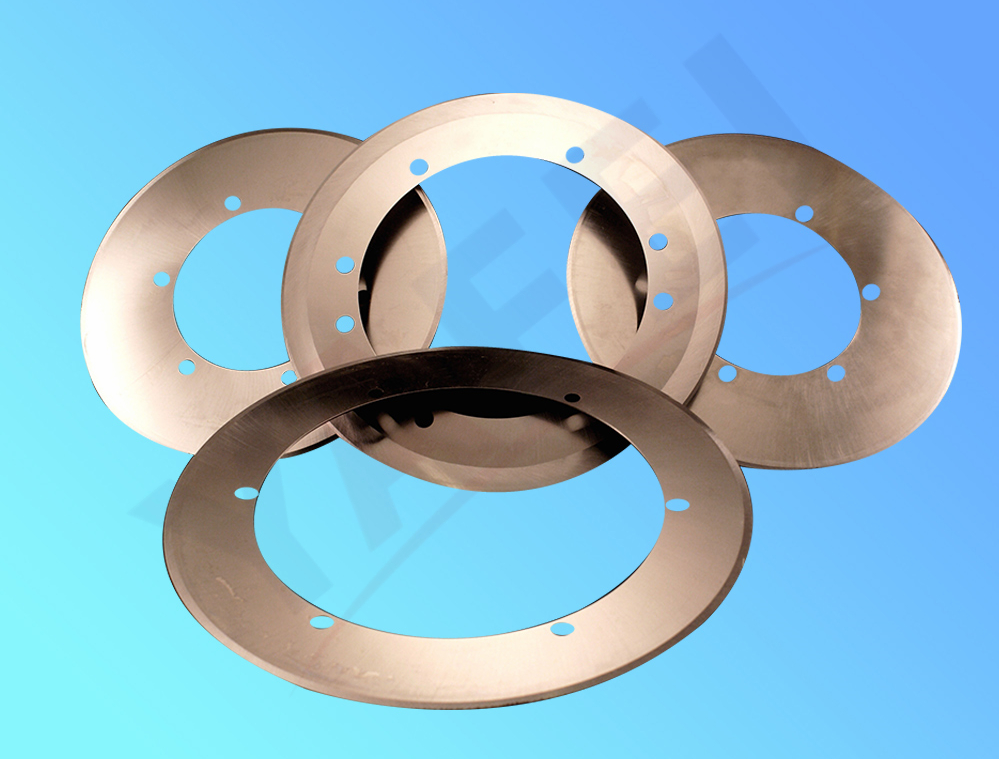

We supply standard and custom designs. Our product range for the corrugated cardboard industry includes.

Including but not limited: carbide slitting knife, Cross Cutting knife, Circular Knives and Straight Knives with and without teeth, grind wheel, etc.

| Availability: | |

|---|---|

| Quantity: | |

Paper Cardboard Straight Sheeter Blades, a precision-engineered product from Yafei Knives, are designed for use in straight sheeting machines—equipment that cuts large rolls or sheets of paper and cardboard into smaller, uniform sizes for packaging, printing, or manufacturing. These blades are the backbone of paper and cardboard processing, delivering clean, straight cuts that ensure finished products (e.g., cardboard boxes, printed flyers, paper bags) have consistent dimensions and professional edges. Unlike generic sheeter blades that often produce jagged cuts or wear down quickly when processing thick cardboard, Yafei’s straight sheeter blades are crafted from high-quality materials and ground to exact tolerances. This attention to detail ensures that the blades maintain sharpness and precision even under high-volume use, making them ideal for paper mills, packaging facilities, and large-scale print shops.

The defining feature of these blades is their ultra-sharp, precision-ground straight edges. Each blade is manufactured using advanced grinding technology to ensure that the cutting edge is perfectly straight and uniformly sharp across its entire length. This precision eliminates “wavy” cuts or uneven edges—common issues with poorly ground blades—that can render cardboard boxes or printed materials unmarketable. The straight edges also ensure that cuts are consistent, even when processing large rolls of paper or cardboard at high speeds (a requirement for large-scale production).

Paper and cardboard sheeting machines operate under constant pressure, especially when cutting thick materials like corrugated cardboard or heavy paperboard. Yafei’s Paper Cardboard Straight Sheeter Blades are made from high-grade hardened tool steel, selected for its ability to withstand continuous pressure and friction without dulling or chipping. The steel is heat-treated to enhance hardness and toughness, ensuring that the blades can handle daily use in high-volume facilities without frequent replacement. For even greater durability, some blade models include carbide inserts along the cutting edge—extending service life for facilities processing extremely thick or abrasive materials.

These blades are designed to integrate seamlessly with most standard straight sheeting machines, including those used for paper, cardboard, and corrugated cardboard. Yafei offers a range of blade sizes and mounting options to match different machine designs, and also provides compatible knife holders to ensure proper blade alignment. Proper alignment is critical for maintaining cut precision and preventing blade damage, so Yafei’s blades and holders are engineered to work together as a system—reducing setup time and minimizing errors.

Paper mills and cardboard manufacturers use straight sheeting machines (equipped with these blades) to cut large rolls of paper or cardboard into standard sheet sizes (e.g., letter, A4, or custom sizes) for distribution to print shops or packaging facilities. The blades’ precision ensures that each sheet is uniformly sized, making it easier for downstream users to process the material without additional trimming. For corrugated cardboard manufacturers, the blades handle thick, multi-layered cardboard without tearing or crushing the flutes (the wavy layer that gives corrugated cardboard its strength).

Packaging facilities rely on Paper Cardboard Straight Sheeter Blades to cut cardboard into flat sheets that are then folded and glued into boxes, cartons, or packaging inserts. The clean, straight cuts ensure that boxes have tight seams and uniform dimensions—critical for protecting products during shipping and maintaining brand consistency. The blades also cut paper for packaging materials like paper bags, tissue paper inserts, or wrapping paper, ensuring these materials are easy to fold and use.

Large-scale print shops use straight sheeting machines to cut rolls of printing paper (e.g., offset paper, glossy paper) into sheets that fit their printing presses. The blades’ precision ensures that each sheet is perfectly sized, preventing paper jams in presses and ensuring that printed materials (e.g., brochures, catalogs, posters) have clean, even edges. The blades also handle thick paperboard for items like book covers, postcards, or greeting cards, delivering the sharp cuts needed for high-quality print finishes.

These blades are designed to cut a wide range of thicknesses, from thin printing paper and tissue paper to thick corrugated cardboard and paperboard. The hardened steel construction handles thicker materials without struggling, and carbide-reinforced models are available for extremely thick or abrasive substrates.

Yafei recommends using the compatible knife holders designed for these blades—they are engineered to hold the blades in perfect alignment. Additionally, follow your sheeting machine’s maintenance guidelines for blade installation, and check alignment periodically (e.g., after replacing blades) to ensure cuts remain straight.

Sharpening frequency depends on usage volume and material thickness. For facilities processing thin paper 8+ hours daily, sharpening every 2–3 months is typical. For facilities cutting thick cardboard, sharpening may be needed every 1–2 months. The blades can be sharpened multiple times before replacement.

Yes, Yafei offers custom-sized blades to match your specific sheeting needs. Whether you need blades for a non-standard sheet size or a specialized sheeting machine, provide the required blade length, thickness, and mounting details, and the team will manufacture blades to your specifications.

Paper Cardboard Straight Sheeter Blades, a precision-engineered product from Yafei Knives, are designed for use in straight sheeting machines—equipment that cuts large rolls or sheets of paper and cardboard into smaller, uniform sizes for packaging, printing, or manufacturing. These blades are the backbone of paper and cardboard processing, delivering clean, straight cuts that ensure finished products (e.g., cardboard boxes, printed flyers, paper bags) have consistent dimensions and professional edges. Unlike generic sheeter blades that often produce jagged cuts or wear down quickly when processing thick cardboard, Yafei’s straight sheeter blades are crafted from high-quality materials and ground to exact tolerances. This attention to detail ensures that the blades maintain sharpness and precision even under high-volume use, making them ideal for paper mills, packaging facilities, and large-scale print shops.

The defining feature of these blades is their ultra-sharp, precision-ground straight edges. Each blade is manufactured using advanced grinding technology to ensure that the cutting edge is perfectly straight and uniformly sharp across its entire length. This precision eliminates “wavy” cuts or uneven edges—common issues with poorly ground blades—that can render cardboard boxes or printed materials unmarketable. The straight edges also ensure that cuts are consistent, even when processing large rolls of paper or cardboard at high speeds (a requirement for large-scale production).

Paper and cardboard sheeting machines operate under constant pressure, especially when cutting thick materials like corrugated cardboard or heavy paperboard. Yafei’s Paper Cardboard Straight Sheeter Blades are made from high-grade hardened tool steel, selected for its ability to withstand continuous pressure and friction without dulling or chipping. The steel is heat-treated to enhance hardness and toughness, ensuring that the blades can handle daily use in high-volume facilities without frequent replacement. For even greater durability, some blade models include carbide inserts along the cutting edge—extending service life for facilities processing extremely thick or abrasive materials.

These blades are designed to integrate seamlessly with most standard straight sheeting machines, including those used for paper, cardboard, and corrugated cardboard. Yafei offers a range of blade sizes and mounting options to match different machine designs, and also provides compatible knife holders to ensure proper blade alignment. Proper alignment is critical for maintaining cut precision and preventing blade damage, so Yafei’s blades and holders are engineered to work together as a system—reducing setup time and minimizing errors.

Paper mills and cardboard manufacturers use straight sheeting machines (equipped with these blades) to cut large rolls of paper or cardboard into standard sheet sizes (e.g., letter, A4, or custom sizes) for distribution to print shops or packaging facilities. The blades’ precision ensures that each sheet is uniformly sized, making it easier for downstream users to process the material without additional trimming. For corrugated cardboard manufacturers, the blades handle thick, multi-layered cardboard without tearing or crushing the flutes (the wavy layer that gives corrugated cardboard its strength).

Packaging facilities rely on Paper Cardboard Straight Sheeter Blades to cut cardboard into flat sheets that are then folded and glued into boxes, cartons, or packaging inserts. The clean, straight cuts ensure that boxes have tight seams and uniform dimensions—critical for protecting products during shipping and maintaining brand consistency. The blades also cut paper for packaging materials like paper bags, tissue paper inserts, or wrapping paper, ensuring these materials are easy to fold and use.

Large-scale print shops use straight sheeting machines to cut rolls of printing paper (e.g., offset paper, glossy paper) into sheets that fit their printing presses. The blades’ precision ensures that each sheet is perfectly sized, preventing paper jams in presses and ensuring that printed materials (e.g., brochures, catalogs, posters) have clean, even edges. The blades also handle thick paperboard for items like book covers, postcards, or greeting cards, delivering the sharp cuts needed for high-quality print finishes.

These blades are designed to cut a wide range of thicknesses, from thin printing paper and tissue paper to thick corrugated cardboard and paperboard. The hardened steel construction handles thicker materials without struggling, and carbide-reinforced models are available for extremely thick or abrasive substrates.

Yafei recommends using the compatible knife holders designed for these blades—they are engineered to hold the blades in perfect alignment. Additionally, follow your sheeting machine’s maintenance guidelines for blade installation, and check alignment periodically (e.g., after replacing blades) to ensure cuts remain straight.

Sharpening frequency depends on usage volume and material thickness. For facilities processing thin paper 8+ hours daily, sharpening every 2–3 months is typical. For facilities cutting thick cardboard, sharpening may be needed every 1–2 months. The blades can be sharpened multiple times before replacement.

Yes, Yafei offers custom-sized blades to match your specific sheeting needs. Whether you need blades for a non-standard sheet size or a specialized sheeting machine, provide the required blade length, thickness, and mounting details, and the team will manufacture blades to your specifications.