- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

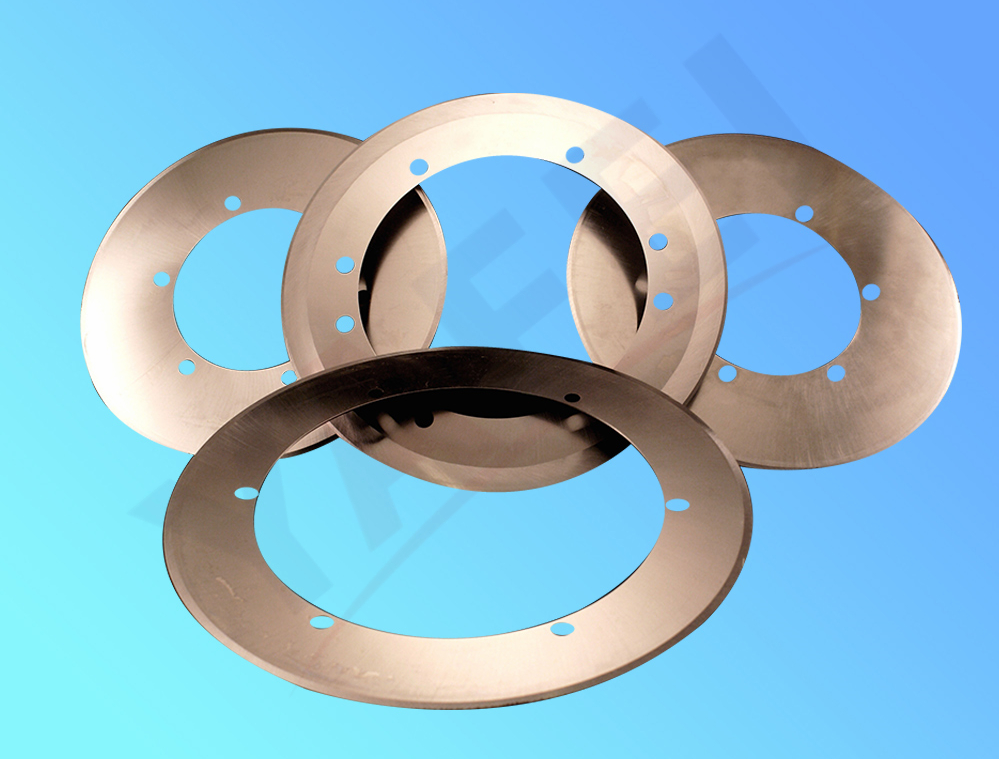

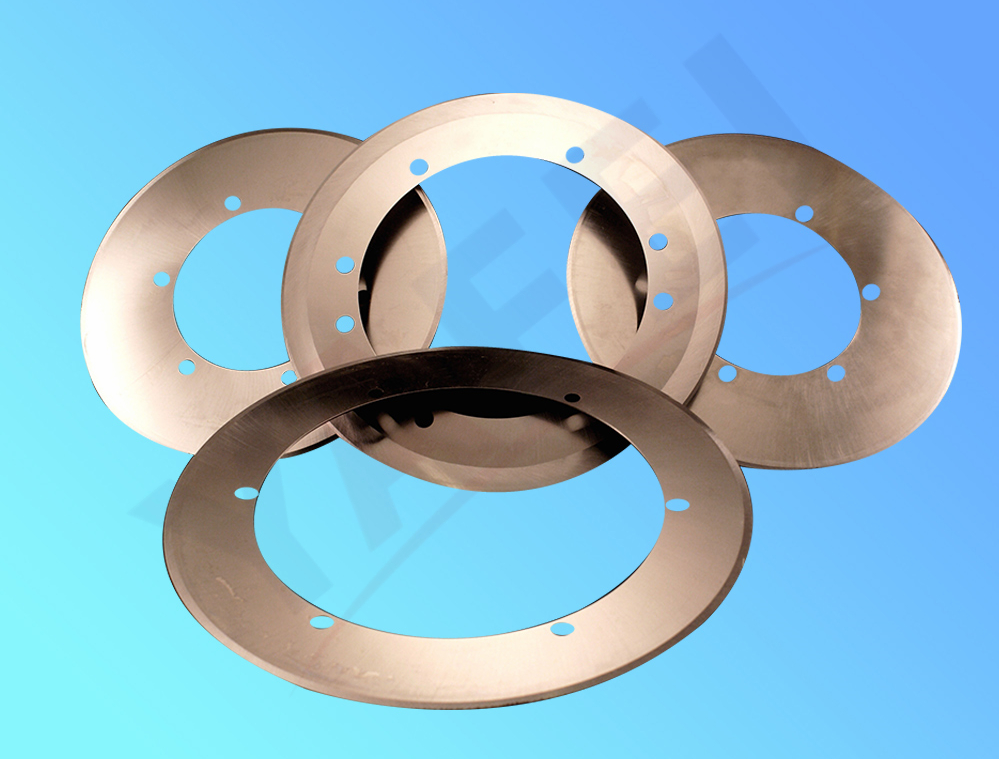

The OD66-150mm Paper Circular Slitting Knives are high-performance rotary cutting tools engineered for the global paper processing industry. Covering a versatile outer diameter range from 66mm to 150mm, these precision blades pair with standard inner diameters (35mm to 95mm) and thicknesses (1.0mm to 2.0mm) to fit most mainstream slitting machines.

Designed for seamless integration into paper converting lines, they deliver consistent cuts across pulp, tissue, cardboard, and corrugated materials. Whether paired with top/bottom knife holders or standalone rotary systems, these blades meet OEM specifications for machines like Agnati, BHS, and Fosber.

Premium Substrates: Available in tungsten carbide, high-speed steel (HSS-M2), and carbon tool steel, reaching 64 HRC hardness for wear resistance.

Micron-Level Tolerance: Cutting edge precision controlled within ±0.0005 inches, ensuring burr-free and dustless cuts to avoid material waste.

Inner Diameter (ID) Customization: Adjusted to match non-standard spindle sizes of specialized slitting/processing machines (e.g., ID50mm for custom tissue machines, ID90mm for unique cardboard equipment).

Thickness Customization: Modified based on material weight and processing tension (e.g., 0.8mm for ultra-thin non-woven fabrics, 2.5mm for extra-heavy corrugated cardboard).

A low friction coefficient effectively curbs the generation of heat during high - speed rotation. This is crucial as excessive heat can cause damage to components and reduce their performance. By minimizing heat buildup, the overall efficiency and durability of the system are enhanced.

The product also showcases high resistance to corrosion and edge chipping. Corrosion can deteriorate the material over time, weakening its structure, while edge chipping can lead to inaccurate cutting or grinding. Compared to generic blades, this product has the remarkable ability to extend its service life by a significant 30%. This extended lifespan not only reduces the frequency of replacements but also offers cost - effectiveness to the users.

Furthermore, it is designed to be compatible with CBN (Cubic Boron Nitride) grinding wheels. This compatibility enables easy reconditioning of the product. CBN grinding wheels are known for their high hardness and precision, making the reconditioning process more efficient and ensuring that the product can maintain its optimal performance over an extended period.

Commercial Buildings: The facades of shopping malls, the exteriors of office buildings, and the entrances of hotels are prime applications. The black color not only enhances the brand image, projecting an air of sophistication and professionalism, but also proves highly durable against the substantial foot traffic these areas typically experience. This color choice makes a strong visual statement while being practical for high - traffic commercial environments.

Residential Properties: For villa exteriors, townhouse walls, and the facades of luxury homes, it offers a unique aesthetic. The addition of a wooden grain pattern brings a touch of warmth. In modern or minimalist designs, where sleekness and simplicity often dominate, the wooden grain provides a natural and inviting contrast. It softens the contemporary lines, creating a more homely and welcoming atmosphere for the residents.

They handle all paper-based materials: pulp (wet/dry), tissue (10-30gsm), cardboard (1-5mm thick), and corrugated board. For non-paper substrates like plastic films, contact us for specialized coatings.

Yes. We offer custom OD (66-150mm), ID (35-120mm), and thickness (1.0-5.0mm) to match your machine model (e.g., Mitsubishi, Gopfert). Lead time for custom blades is 5-7 business days.

Service life depends on material and usage:

Tissue slitting: 2,000+ hours

Corrugated cardboard: 800-1,200 hours

Regular inspection for edge dullness is recommended to maintain precision.

We stock blades compatible with 95% of global paper slitting equipment, including Top/Bottom Slitter Knife Systems and rotary cutters. Provide your machine brand/model for confirmation.

The OD66-150mm Paper Circular Slitting Knives are high-performance rotary cutting tools engineered for the global paper processing industry. Covering a versatile outer diameter range from 66mm to 150mm, these precision blades pair with standard inner diameters (35mm to 95mm) and thicknesses (1.0mm to 2.0mm) to fit most mainstream slitting machines.

Designed for seamless integration into paper converting lines, they deliver consistent cuts across pulp, tissue, cardboard, and corrugated materials. Whether paired with top/bottom knife holders or standalone rotary systems, these blades meet OEM specifications for machines like Agnati, BHS, and Fosber.

Premium Substrates: Available in tungsten carbide, high-speed steel (HSS-M2), and carbon tool steel, reaching 64 HRC hardness for wear resistance.

Micron-Level Tolerance: Cutting edge precision controlled within ±0.0005 inches, ensuring burr-free and dustless cuts to avoid material waste.

Inner Diameter (ID) Customization: Adjusted to match non-standard spindle sizes of specialized slitting/processing machines (e.g., ID50mm for custom tissue machines, ID90mm for unique cardboard equipment).

Thickness Customization: Modified based on material weight and processing tension (e.g., 0.8mm for ultra-thin non-woven fabrics, 2.5mm for extra-heavy corrugated cardboard).

A low friction coefficient effectively curbs the generation of heat during high - speed rotation. This is crucial as excessive heat can cause damage to components and reduce their performance. By minimizing heat buildup, the overall efficiency and durability of the system are enhanced.

The product also showcases high resistance to corrosion and edge chipping. Corrosion can deteriorate the material over time, weakening its structure, while edge chipping can lead to inaccurate cutting or grinding. Compared to generic blades, this product has the remarkable ability to extend its service life by a significant 30%. This extended lifespan not only reduces the frequency of replacements but also offers cost - effectiveness to the users.

Furthermore, it is designed to be compatible with CBN (Cubic Boron Nitride) grinding wheels. This compatibility enables easy reconditioning of the product. CBN grinding wheels are known for their high hardness and precision, making the reconditioning process more efficient and ensuring that the product can maintain its optimal performance over an extended period.

Commercial Buildings: The facades of shopping malls, the exteriors of office buildings, and the entrances of hotels are prime applications. The black color not only enhances the brand image, projecting an air of sophistication and professionalism, but also proves highly durable against the substantial foot traffic these areas typically experience. This color choice makes a strong visual statement while being practical for high - traffic commercial environments.

Residential Properties: For villa exteriors, townhouse walls, and the facades of luxury homes, it offers a unique aesthetic. The addition of a wooden grain pattern brings a touch of warmth. In modern or minimalist designs, where sleekness and simplicity often dominate, the wooden grain provides a natural and inviting contrast. It softens the contemporary lines, creating a more homely and welcoming atmosphere for the residents.

They handle all paper-based materials: pulp (wet/dry), tissue (10-30gsm), cardboard (1-5mm thick), and corrugated board. For non-paper substrates like plastic films, contact us for specialized coatings.

Yes. We offer custom OD (66-150mm), ID (35-120mm), and thickness (1.0-5.0mm) to match your machine model (e.g., Mitsubishi, Gopfert). Lead time for custom blades is 5-7 business days.

Service life depends on material and usage:

Tissue slitting: 2,000+ hours

Corrugated cardboard: 800-1,200 hours

Regular inspection for edge dullness is recommended to maintain precision.

We stock blades compatible with 95% of global paper slitting equipment, including Top/Bottom Slitter Knife Systems and rotary cutters. Provide your machine brand/model for confirmation.