- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

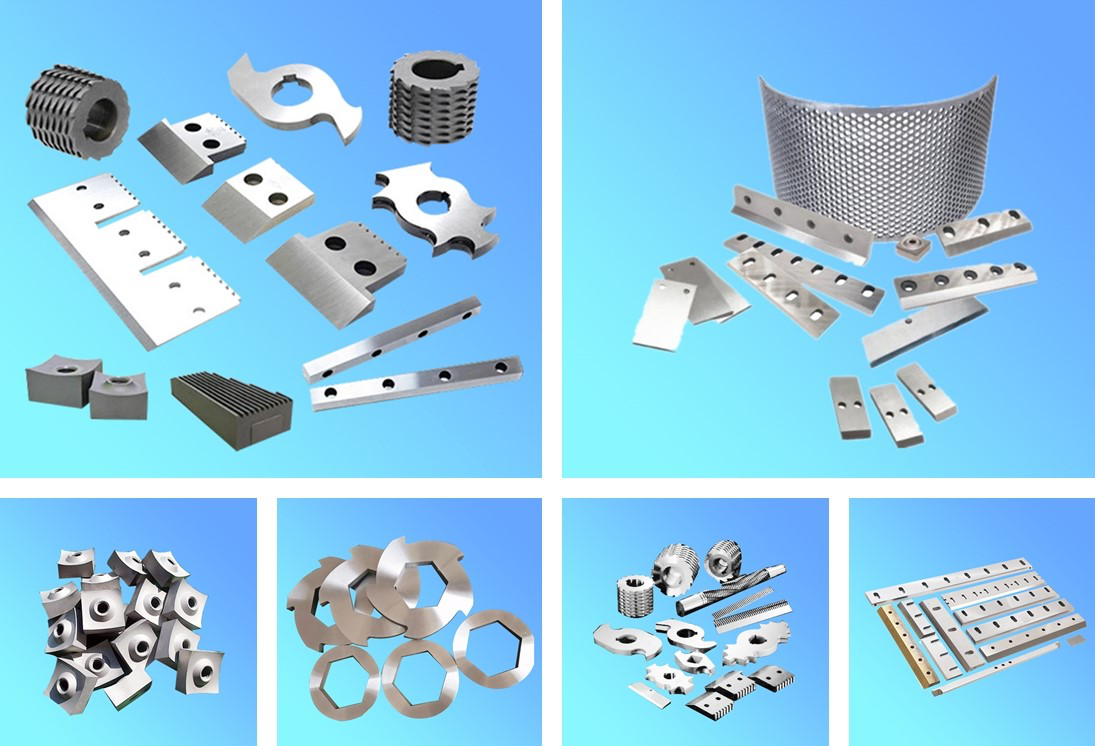

We can customize the blades of various sizes according to your requirements. Our technicians and specialists know all the granulating systems, granulators, cutting mills and recycling plants for the processing of plastics, rubber and recycled products. Shredder knives for shredding and volume reduction of municipal and industrial waste, WEEE, tyres, plastic, paper, cables, aluminum, copper, pulp, biomass, rubber, wood, pallets, medical waste, oil filters, textiles, batteries, etc.

| Availability: | |

|---|---|

| Quantity: | |

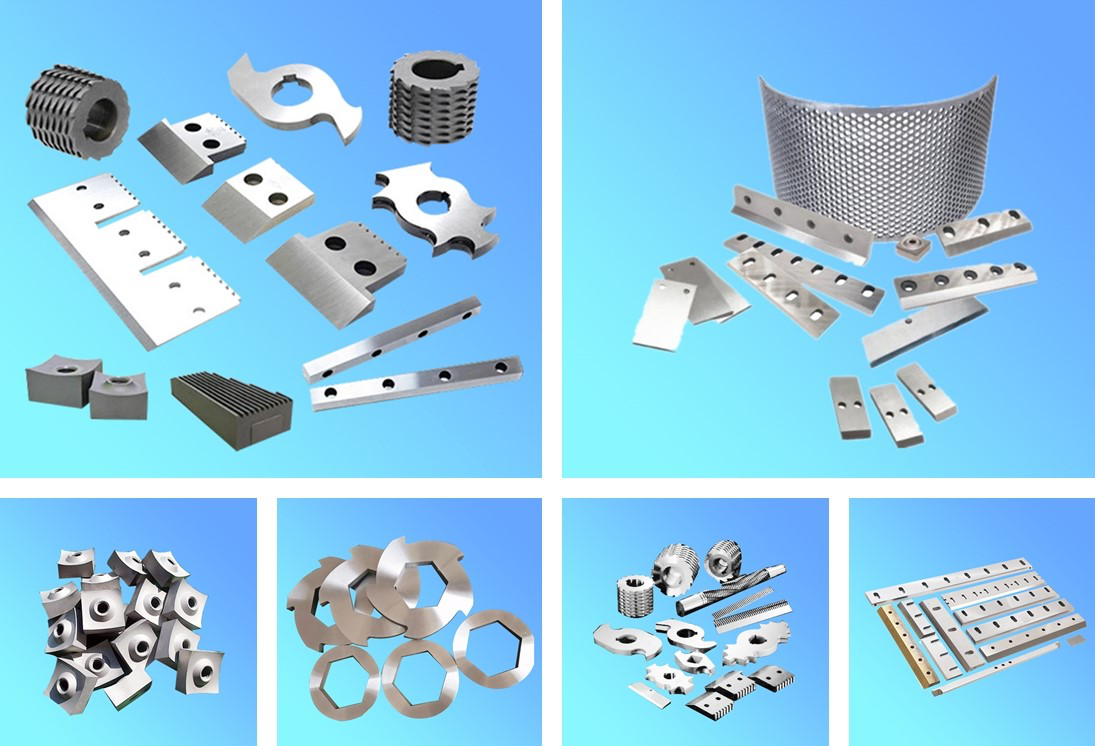

ANHUI YAFEI, a leading manufacturer of industrial shredding components, presents our Rotor and Stationary Shredder Knives—a complementary set of blades designed to work together to maximize the efficiency and performance of shredding machines. Rotor knives are mounted on the rotating shaft of the shredder, while stationary knives are fixed in place, creating a "shearing" action that breaks down materials into smaller pieces. Crafted from high-strength alloys and engineered for precision, our knives are built to handle the toughest shredding tasks, from processing industrial waste to recycling bulky materials. Whether you operate a waste management facility, a recycling plant, or a manufacturing site with scrap processing needs, our Rotor and Stationary Shredder Knives deliver reliable performance that minimizes downtime and reduces operational costs.

The rotor and stationary knives are designed to work in perfect harmony, with the rotating rotor knives pushing materials against the fixed stationary knives to create a powerful shearing force. This design ensures that even large or tough materials are broken down quickly and uniformly, reducing the time needed to process each load. The precise alignment of the knives also prevents material from slipping between the blades, eliminating jams and ensuring consistent shredding results.

We use premium, heat-treated alloys to manufacture our Rotor and Stationary Shredder Knives. These alloys are selected for their ability to withstand impact, abrasion, and high temperatures—common challenges in shredding operations. The rotor knives, which experience more wear due to their constant rotation, are made from a harder alloy variant to enhance their durability, while the stationary knives are designed to maintain their shape and edge even under continuous pressure.

Shredding machines come in a variety of sizes and configurations, which is why we offer custom Rotor and Stationary Shredder Knives tailored to your equipment’s specifications. We can adjust the knife’s size, shape, number of teeth (if applicable), and mounting style to match your shredder’s rotor design and processing capacity. Whether you have a small single-shaft shredder or a large industrial shredder, our team can create a knife set that fits perfectly and optimizes performance.

Our knives are designed with user-friendliness in mind, featuring simple mounting mechanisms that allow for quick and easy installation or replacement. We also provide detailed maintenance guidelines, including tips on sharpening the knives and inspecting them for wear. The durable construction of the knives means they require less frequent maintenance, but regular checks can help identify potential issues early and prevent unexpected downtime.

Our Rotor and Stationary Shredder Knives are versatile enough to handle a wide range of shredding applications across industries, including:

• Waste Management Facilities: Shredding municipal solid waste, organic waste, and construction debris to reduce volume for landfilling or recycling.

• Recycling Plants: Processing recyclable materials such as plastic scraps, rubber tires, aluminum cans, and waste paper into small particles for further recycling.

• Manufacturing Plants: Breaking down industrial scrap, such as metal shavings, plastic scraps, and wood chips, for reuse or disposal.

• Automotive Recycling Facilities: Shredding car parts, tires, and plastic components from end-of-life vehicles to recover valuable materials like metal and rubber.

Proper alignment is critical for efficient shredding. If the knives are misaligned, materials may slip between them, causing jams or uneven shredding. Misalignment can also lead to excessive wear on both knives, reducing their lifespan. We recommend checking the alignment regularly and following our installation guidelines to ensure the knives are positioned correctly.

In most cases, you can replace just the rotor knives if they are more worn than the stationary knives (since rotor knives experience more movement and wear). However, if the stationary knives are also dull or damaged, replacing both sets together will ensure optimal performance and prevent uneven wear on the new rotor knives. Our team can help assess the condition of your knives and recommend the right replacement strategy.

We recommend three key maintenance steps: regular inspection (to check for dullness, chips, or misalignment), proper lubrication of the shredder’s moving parts (to reduce friction on the knives), and timely sharpening (when signs of dullness appear). Avoid processing materials that are harder than the knife’s material (e.g., rocks or metal chunks), as this can cause irreversible damage.

Yes, we provide a standard warranty on all our knives, covering defects in materials and manufacturing. The length of the warranty depends on the material of the knives (carbide knives have a longer warranty than alloy knives) and the application. Our team can provide detailed warranty terms based on your specific order, and we stand behind our products with responsive after-sales support.

ANHUI YAFEI, a leading manufacturer of industrial shredding components, presents our Rotor and Stationary Shredder Knives—a complementary set of blades designed to work together to maximize the efficiency and performance of shredding machines. Rotor knives are mounted on the rotating shaft of the shredder, while stationary knives are fixed in place, creating a "shearing" action that breaks down materials into smaller pieces. Crafted from high-strength alloys and engineered for precision, our knives are built to handle the toughest shredding tasks, from processing industrial waste to recycling bulky materials. Whether you operate a waste management facility, a recycling plant, or a manufacturing site with scrap processing needs, our Rotor and Stationary Shredder Knives deliver reliable performance that minimizes downtime and reduces operational costs.

The rotor and stationary knives are designed to work in perfect harmony, with the rotating rotor knives pushing materials against the fixed stationary knives to create a powerful shearing force. This design ensures that even large or tough materials are broken down quickly and uniformly, reducing the time needed to process each load. The precise alignment of the knives also prevents material from slipping between the blades, eliminating jams and ensuring consistent shredding results.

We use premium, heat-treated alloys to manufacture our Rotor and Stationary Shredder Knives. These alloys are selected for their ability to withstand impact, abrasion, and high temperatures—common challenges in shredding operations. The rotor knives, which experience more wear due to their constant rotation, are made from a harder alloy variant to enhance their durability, while the stationary knives are designed to maintain their shape and edge even under continuous pressure.

Shredding machines come in a variety of sizes and configurations, which is why we offer custom Rotor and Stationary Shredder Knives tailored to your equipment’s specifications. We can adjust the knife’s size, shape, number of teeth (if applicable), and mounting style to match your shredder’s rotor design and processing capacity. Whether you have a small single-shaft shredder or a large industrial shredder, our team can create a knife set that fits perfectly and optimizes performance.

Our knives are designed with user-friendliness in mind, featuring simple mounting mechanisms that allow for quick and easy installation or replacement. We also provide detailed maintenance guidelines, including tips on sharpening the knives and inspecting them for wear. The durable construction of the knives means they require less frequent maintenance, but regular checks can help identify potential issues early and prevent unexpected downtime.

Our Rotor and Stationary Shredder Knives are versatile enough to handle a wide range of shredding applications across industries, including:

• Waste Management Facilities: Shredding municipal solid waste, organic waste, and construction debris to reduce volume for landfilling or recycling.

• Recycling Plants: Processing recyclable materials such as plastic scraps, rubber tires, aluminum cans, and waste paper into small particles for further recycling.

• Manufacturing Plants: Breaking down industrial scrap, such as metal shavings, plastic scraps, and wood chips, for reuse or disposal.

• Automotive Recycling Facilities: Shredding car parts, tires, and plastic components from end-of-life vehicles to recover valuable materials like metal and rubber.

Proper alignment is critical for efficient shredding. If the knives are misaligned, materials may slip between them, causing jams or uneven shredding. Misalignment can also lead to excessive wear on both knives, reducing their lifespan. We recommend checking the alignment regularly and following our installation guidelines to ensure the knives are positioned correctly.

In most cases, you can replace just the rotor knives if they are more worn than the stationary knives (since rotor knives experience more movement and wear). However, if the stationary knives are also dull or damaged, replacing both sets together will ensure optimal performance and prevent uneven wear on the new rotor knives. Our team can help assess the condition of your knives and recommend the right replacement strategy.

We recommend three key maintenance steps: regular inspection (to check for dullness, chips, or misalignment), proper lubrication of the shredder’s moving parts (to reduce friction on the knives), and timely sharpening (when signs of dullness appear). Avoid processing materials that are harder than the knife’s material (e.g., rocks or metal chunks), as this can cause irreversible damage.

Yes, we provide a standard warranty on all our knives, covering defects in materials and manufacturing. The length of the warranty depends on the material of the knives (carbide knives have a longer warranty than alloy knives) and the application. Our team can provide detailed warranty terms based on your specific order, and we stand behind our products with responsive after-sales support.