- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

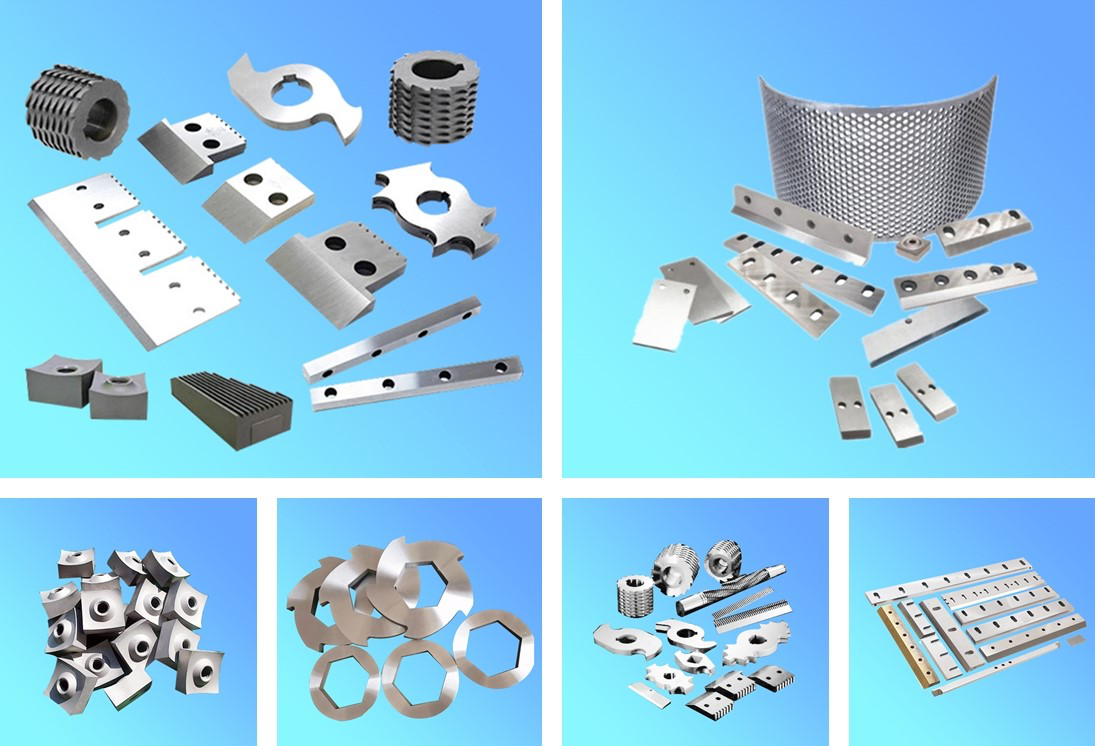

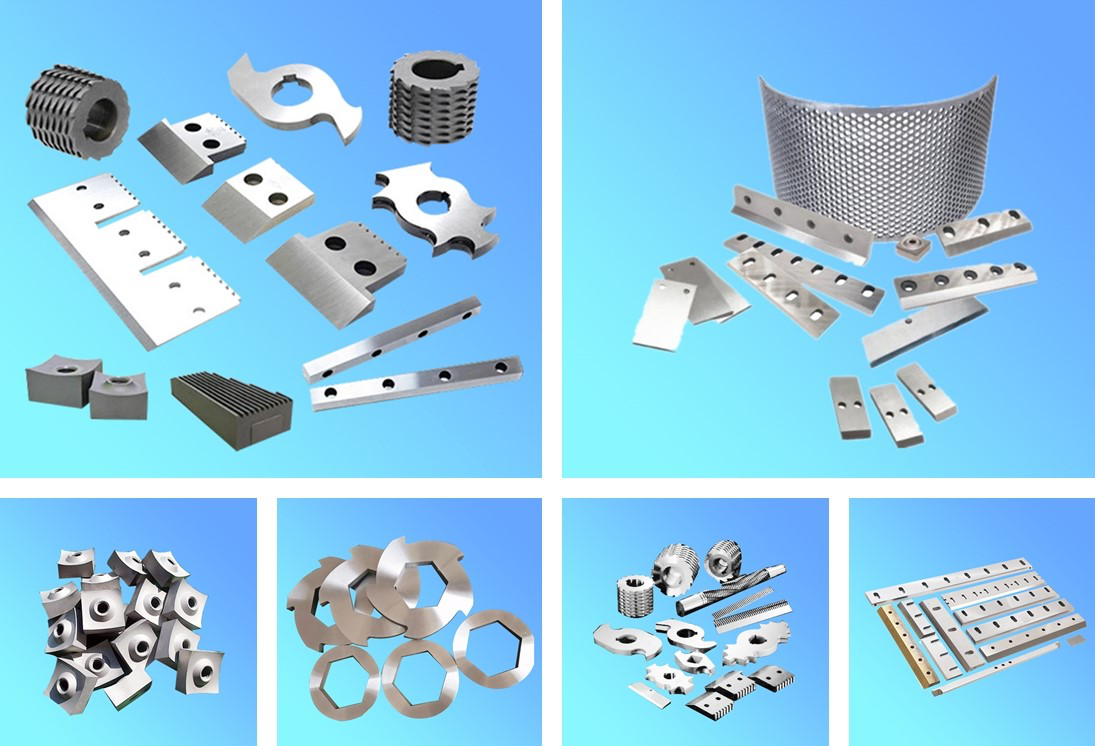

We can customize the blades of various sizes according to your requirements. Our technicians and specialists know all the granulating systems, granulators, cutting mills and recycling plants for the processing of plastics, rubber and recycled products. Shredder knives for shredding and volume reduction of municipal and industrial waste, WEEE, tyres, plastic, paper, cables, aluminum, copper, pulp, biomass, rubber, wood, pallets, medical waste, oil filters, textiles, batteries, etc.

| Availability: | |

|---|---|

| Quantity: | |

High-Strength Plastic Rubber Crusher Knives are durable, precision-engineered cutting tools designed for the efficient crushing of plastic and rubber materials in recycling and waste processing operations. Unlike standard crusher knives that may flex or wear out when handling tough, elastic plastic or rubber, these high-strength knives are built to withstand the mechanical stress of continuous crushing, delivering consistent performance over time. They are a core component in facilities that process plastic waste (such as discarded bottles, industrial scraps, or packaging) and rubber waste (like old tyres, hoses, or gaskets), playing a key role in reducing waste volume and preparing materials for recycling. Manufactured with materials that prioritize strength and resilience, these knives ensure that plastic and rubber are crushed into uniform, manageable pieces, supporting smooth downstream processing (such as melting for plastic recycling or grinding for rubber granules). Whether used in small recycling centers or large industrial facilities, they help improve operational efficiency and reduce maintenance costs.

These knives are made from high-strength alloy materials that offer exceptional tensile strength— the ability to resist breaking or deforming under tension. This feature is critical for crushing plastic and rubber, which often require significant force to break down. The high tensile strength ensures the knives maintain their shape even when crushing thick, rigid plastics (like PVC pipes) or tough rubber (like tyre treads), avoiding the bending or warping that can render standard knives ineffective.

The knives feature a precise edge profile and balanced design that ensures every part of the blade contributes to even crushing. This uniformity prevents the formation of oversized or unevenly crushed pieces, which can clog downstream equipment (like grinders or separators). For example, when crushing plastic bottles, the knives break the material into consistent flakes that are easy to melt and reprocess into new plastic products.

Designed with user convenience in mind, these knives are easy to inspect, clean, and replace. They feature a simple mounting system that allows for quick installation in most standard crusher machines, minimizing downtime during maintenance. Additionally, the materials are resistant to residue buildup (a common issue with sticky plastics), making cleaning faster and more straightforward.

Plastic recycling centers use these knives to crush a wide range of plastic materials, including PET (plastic bottles), HDPE (plastic containers), PP (plastic bags), and PVC (plastic pipes). The uniform crushing action prepares the plastic for washing, sorting, and melting, which are key steps in the recycling process.

Facilities handling rubber waste—such as old tyres, rubber mats, or industrial rubber scraps—rely on these knives to crush the material into smaller pieces. These pieces can then be further processed into rubber granules (used in playground surfaces or road asphalt) or reclaimed rubber (used in manufacturing new rubber products).

Many manufacturing industries (like automotive, electronics, or packaging) produce plastic and rubber scraps during production. These knives are used in on-site waste management systems to crush the scraps, reducing the volume of waste that needs to be transported to external recycling facilities. This not only lowers transportation costs but also supports on-site material reuse (e.g., crushing plastic scraps to reintroduce into the production process).

Yes, these knives are designed to handle both hard and soft plastics. The high tensile strength allows them to crush rigid plastics (like HDPE or PVC) without deformation, while the precise edge profile ensures soft plastics (like LDPE or plastic films) are cut cleanly without being pulled or stretched. This versatility makes them suitable for mixed plastic waste streams common in recycling facilities.

On average, High-Strength Plastic Rubber Crusher Knives last 2–3 times longer than standard crusher knives. This extended lifespan is due to their high-strength material construction and wear resistance, which reduce the frequency of replacements. For high-volume operations (processing several tons of material daily), this translates to significant cost savings on blade purchases and reduced downtime for maintenance.

No special lubrication is required. Routine care involves regular inspections to check for dullness, damage, or residue buildup. If residue (like sticky plastic) accumulates on the blade, it can be cleaned with a food-safe or industrial-grade cleaning agent (depending on the application) and a soft brush. For dull blades, professional sharpening is recommended to restore cutting performance—this can be done 2–3 times before replacement is needed, further extending the knife’s lifespan.

High-Strength Plastic Rubber Crusher Knives are durable, precision-engineered cutting tools designed for the efficient crushing of plastic and rubber materials in recycling and waste processing operations. Unlike standard crusher knives that may flex or wear out when handling tough, elastic plastic or rubber, these high-strength knives are built to withstand the mechanical stress of continuous crushing, delivering consistent performance over time. They are a core component in facilities that process plastic waste (such as discarded bottles, industrial scraps, or packaging) and rubber waste (like old tyres, hoses, or gaskets), playing a key role in reducing waste volume and preparing materials for recycling. Manufactured with materials that prioritize strength and resilience, these knives ensure that plastic and rubber are crushed into uniform, manageable pieces, supporting smooth downstream processing (such as melting for plastic recycling or grinding for rubber granules). Whether used in small recycling centers or large industrial facilities, they help improve operational efficiency and reduce maintenance costs.

These knives are made from high-strength alloy materials that offer exceptional tensile strength— the ability to resist breaking or deforming under tension. This feature is critical for crushing plastic and rubber, which often require significant force to break down. The high tensile strength ensures the knives maintain their shape even when crushing thick, rigid plastics (like PVC pipes) or tough rubber (like tyre treads), avoiding the bending or warping that can render standard knives ineffective.

The knives feature a precise edge profile and balanced design that ensures every part of the blade contributes to even crushing. This uniformity prevents the formation of oversized or unevenly crushed pieces, which can clog downstream equipment (like grinders or separators). For example, when crushing plastic bottles, the knives break the material into consistent flakes that are easy to melt and reprocess into new plastic products.

Designed with user convenience in mind, these knives are easy to inspect, clean, and replace. They feature a simple mounting system that allows for quick installation in most standard crusher machines, minimizing downtime during maintenance. Additionally, the materials are resistant to residue buildup (a common issue with sticky plastics), making cleaning faster and more straightforward.

Plastic recycling centers use these knives to crush a wide range of plastic materials, including PET (plastic bottles), HDPE (plastic containers), PP (plastic bags), and PVC (plastic pipes). The uniform crushing action prepares the plastic for washing, sorting, and melting, which are key steps in the recycling process.

Facilities handling rubber waste—such as old tyres, rubber mats, or industrial rubber scraps—rely on these knives to crush the material into smaller pieces. These pieces can then be further processed into rubber granules (used in playground surfaces or road asphalt) or reclaimed rubber (used in manufacturing new rubber products).

Many manufacturing industries (like automotive, electronics, or packaging) produce plastic and rubber scraps during production. These knives are used in on-site waste management systems to crush the scraps, reducing the volume of waste that needs to be transported to external recycling facilities. This not only lowers transportation costs but also supports on-site material reuse (e.g., crushing plastic scraps to reintroduce into the production process).

Yes, these knives are designed to handle both hard and soft plastics. The high tensile strength allows them to crush rigid plastics (like HDPE or PVC) without deformation, while the precise edge profile ensures soft plastics (like LDPE or plastic films) are cut cleanly without being pulled or stretched. This versatility makes them suitable for mixed plastic waste streams common in recycling facilities.

On average, High-Strength Plastic Rubber Crusher Knives last 2–3 times longer than standard crusher knives. This extended lifespan is due to their high-strength material construction and wear resistance, which reduce the frequency of replacements. For high-volume operations (processing several tons of material daily), this translates to significant cost savings on blade purchases and reduced downtime for maintenance.

No special lubrication is required. Routine care involves regular inspections to check for dullness, damage, or residue buildup. If residue (like sticky plastic) accumulates on the blade, it can be cleaned with a food-safe or industrial-grade cleaning agent (depending on the application) and a soft brush. For dull blades, professional sharpening is recommended to restore cutting performance—this can be done 2–3 times before replacement is needed, further extending the knife’s lifespan.