- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

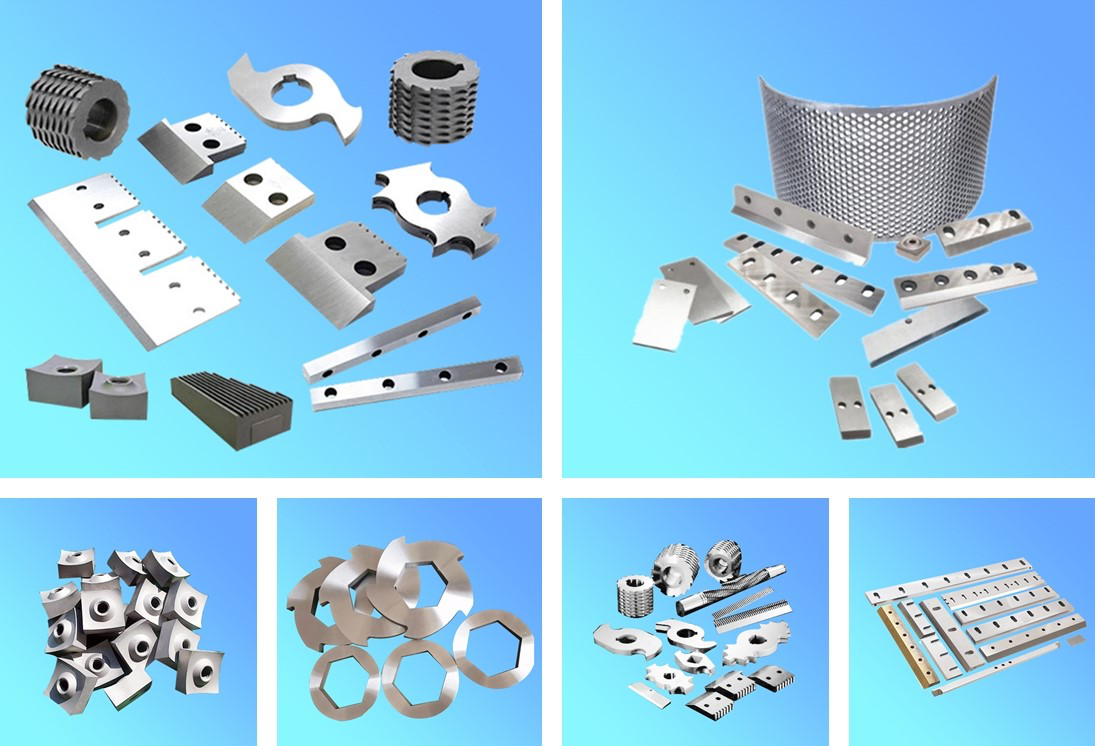

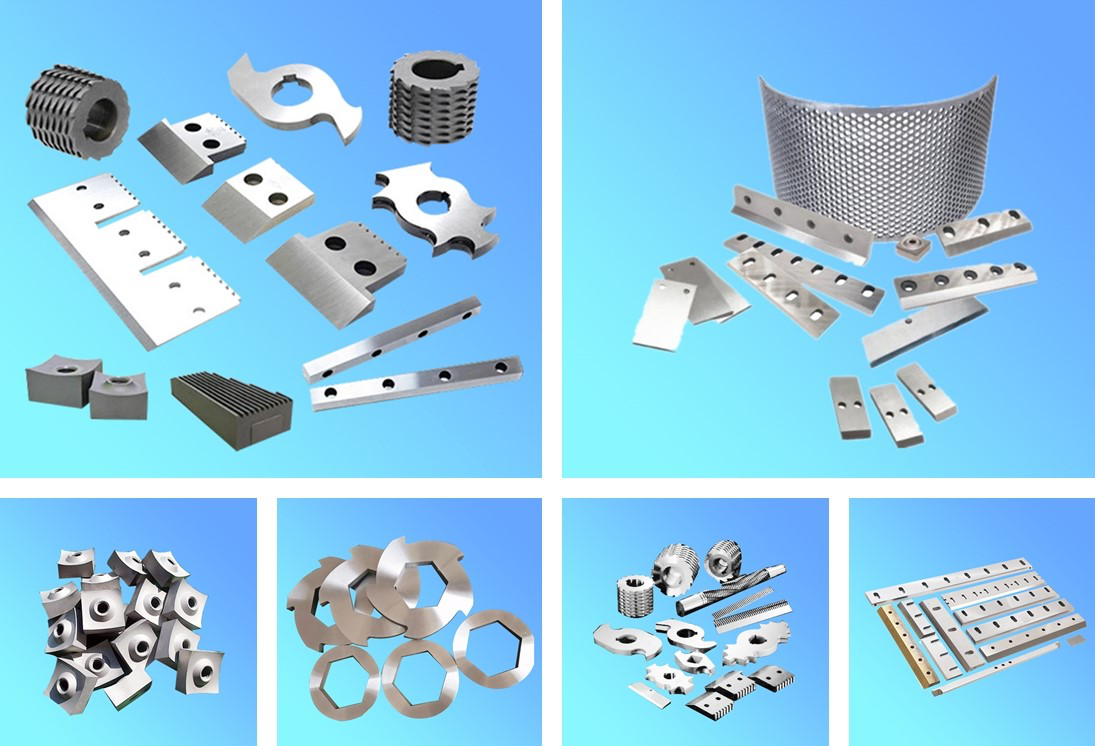

We can customize the blades of various sizes according to your requirements. Our technicians and specialists know all the granulating systems, granulators, cutting mills and recycling plants for the processing of plastics, rubber and recycled products. Shredder knives for shredding and volume reduction of municipal and industrial waste, WEEE, tyres, plastic, paper, cables, aluminum, copper, pulp, biomass, rubber, wood, pallets, medical waste, oil filters, textiles, batteries, etc.

| Availability: | |

|---|---|

| Quantity: | |

Twin Shaft Plastic Shredder Blades, a heavy-duty offering from Yafei Knives, are engineered to power twin-shaft plastic shredders—critical equipment in plastic recycling and waste management. These blades are designed to break down a wide range of plastic materials into uniform, manageable pieces (flakes or pellets) that can be reused in plastic manufacturing or disposed of efficiently. Unlike lightweight shredder blades that dull quickly when faced with tough plastics, Yafei’s twin-shaft blades are built for maximum strength and durability, withstanding the high torque and impact forces of twin-shaft shredders. Their robust construction ensures consistent shredding performance, even when processing thick, rigid plastics or contaminated plastic waste. For plastic recycling facilities, manufacturing plants (handling plastic scrap), and waste management companies, these blades are essential for efficient, cost-effective plastic processing.

Twin-shaft shredders operate by rotating two shafts with interlocking blades, which grab and tear plastic materials—requiring blades that can withstand extreme impact and friction. Yafei’s Twin Shaft Plastic Shredder Blades are crafted from high-grade, hardened alloy steel (with carbide inserts in high-wear areas) that resists chipping, bending, and wear. This material composition ensures that the blades can handle even the toughest plastics (e.g., thick plastic pipes, reinforced plastic containers) without breaking or dulling prematurely. The blades’ strength also reduces the risk of jams, which are common with weaker blades that cannot process rigid materials.

The blades feature a optimized, interlocking tooth design that works in harmony with twin-shaft shredders. Each blade is shaped to grab plastic materials firmly, pull them into the shredder, and tear them into uniform pieces—eliminating uneven shreds that can clog downstream processing equipment (e.g., granulators). The interlocking design also ensures that no plastic passes through unshredded, maximizing shredding efficiency and reducing the need for reprocessing. Whether processing large plastic items (e.g., plastic pallets) or small scrap (e.g., plastic film), the blades deliver consistent results.

Yafei designs Twin Shaft Plastic Shredder Blades to be easy to install and replace, minimizing downtime for maintenance. The blades are manufactured to fit most standard twin-shaft shredder models, with customizable dimensions (length, thickness, mounting holes) available for non-standard machines. This compatibility means that facilities do not need to replace entire shredders to upgrade their blades—simply swap out old blades for Yafei’s high-performance ones to improve efficiency.

Plastic recycling facilities rely on twin-shaft shredders to process post-consumer plastic waste (e.g., plastic bottles, containers, bags) and post-industrial scrap (e.g., plastic trim, defective products) into recyclable flakes. Twin Shaft Plastic Shredder Blades ensure that this waste is shredded into uniform sizes that can be easily washed, melted, and reformed into new plastic products. The blades’ durability allows facilities to process high volumes of plastic waste daily without frequent blade replacements.

Manufacturing plants that produce plastic goods (e.g., injection molding facilities, plastic packaging plants) generate significant amounts of plastic scrap (e.g., excess trim, rejected parts). These blades help plants manage this scrap by shredding it into small pieces that can be reused in the production process (reducing raw material costs) or sent to recycling facilities. The efficient shredding also saves space in waste storage, lowering disposal costs.

Waste management companies and industrial facilities use twin-shaft shredders to process mixed plastic waste (including contaminated or bulky items like plastic drums, crates, or automotive plastic parts). Twin Shaft Plastic Shredder Blades handle these challenging materials, breaking them down into smaller pieces that are easier to transport, sort, or dispose of. For facilities dealing with hazardous plastic waste (e.g., chemical containers), the blades’ robust design ensures safe, efficient shredding without blade failure.

These blades can process nearly all plastic types, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and even reinforced plastics (e.g., plastic with fiberglass). They also handle plastic film, rigid containers, pipes, pallets, and contaminated plastic waste.

In heavy-duty recycling facilities (processing 8+ hours daily), the blades typically last 6–12 months before needing sharpening or replacement—depending on the plastic type (rigid plastics wear blades faster than film). The carbide-reinforced edges extend life compared to standard steel blades.

Yes, the blades can be resharpened multiple times (usually 2–3 times) before replacement is needed. Yafei recommends professional sharpening to maintain the blades’ original shape and performance—improper sharpening can reduce efficiency or cause premature wear.

Yafei offers blades for most standard twin-shaft shredder brands and models. Provide your shredder’s make, model, and shaft dimensions, and the team will confirm compatibility or design custom blades to fit.

Twin Shaft Plastic Shredder Blades, a heavy-duty offering from Yafei Knives, are engineered to power twin-shaft plastic shredders—critical equipment in plastic recycling and waste management. These blades are designed to break down a wide range of plastic materials into uniform, manageable pieces (flakes or pellets) that can be reused in plastic manufacturing or disposed of efficiently. Unlike lightweight shredder blades that dull quickly when faced with tough plastics, Yafei’s twin-shaft blades are built for maximum strength and durability, withstanding the high torque and impact forces of twin-shaft shredders. Their robust construction ensures consistent shredding performance, even when processing thick, rigid plastics or contaminated plastic waste. For plastic recycling facilities, manufacturing plants (handling plastic scrap), and waste management companies, these blades are essential for efficient, cost-effective plastic processing.

Twin-shaft shredders operate by rotating two shafts with interlocking blades, which grab and tear plastic materials—requiring blades that can withstand extreme impact and friction. Yafei’s Twin Shaft Plastic Shredder Blades are crafted from high-grade, hardened alloy steel (with carbide inserts in high-wear areas) that resists chipping, bending, and wear. This material composition ensures that the blades can handle even the toughest plastics (e.g., thick plastic pipes, reinforced plastic containers) without breaking or dulling prematurely. The blades’ strength also reduces the risk of jams, which are common with weaker blades that cannot process rigid materials.

The blades feature a optimized, interlocking tooth design that works in harmony with twin-shaft shredders. Each blade is shaped to grab plastic materials firmly, pull them into the shredder, and tear them into uniform pieces—eliminating uneven shreds that can clog downstream processing equipment (e.g., granulators). The interlocking design also ensures that no plastic passes through unshredded, maximizing shredding efficiency and reducing the need for reprocessing. Whether processing large plastic items (e.g., plastic pallets) or small scrap (e.g., plastic film), the blades deliver consistent results.

Yafei designs Twin Shaft Plastic Shredder Blades to be easy to install and replace, minimizing downtime for maintenance. The blades are manufactured to fit most standard twin-shaft shredder models, with customizable dimensions (length, thickness, mounting holes) available for non-standard machines. This compatibility means that facilities do not need to replace entire shredders to upgrade their blades—simply swap out old blades for Yafei’s high-performance ones to improve efficiency.

Plastic recycling facilities rely on twin-shaft shredders to process post-consumer plastic waste (e.g., plastic bottles, containers, bags) and post-industrial scrap (e.g., plastic trim, defective products) into recyclable flakes. Twin Shaft Plastic Shredder Blades ensure that this waste is shredded into uniform sizes that can be easily washed, melted, and reformed into new plastic products. The blades’ durability allows facilities to process high volumes of plastic waste daily without frequent blade replacements.

Manufacturing plants that produce plastic goods (e.g., injection molding facilities, plastic packaging plants) generate significant amounts of plastic scrap (e.g., excess trim, rejected parts). These blades help plants manage this scrap by shredding it into small pieces that can be reused in the production process (reducing raw material costs) or sent to recycling facilities. The efficient shredding also saves space in waste storage, lowering disposal costs.

Waste management companies and industrial facilities use twin-shaft shredders to process mixed plastic waste (including contaminated or bulky items like plastic drums, crates, or automotive plastic parts). Twin Shaft Plastic Shredder Blades handle these challenging materials, breaking them down into smaller pieces that are easier to transport, sort, or dispose of. For facilities dealing with hazardous plastic waste (e.g., chemical containers), the blades’ robust design ensures safe, efficient shredding without blade failure.

These blades can process nearly all plastic types, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and even reinforced plastics (e.g., plastic with fiberglass). They also handle plastic film, rigid containers, pipes, pallets, and contaminated plastic waste.

In heavy-duty recycling facilities (processing 8+ hours daily), the blades typically last 6–12 months before needing sharpening or replacement—depending on the plastic type (rigid plastics wear blades faster than film). The carbide-reinforced edges extend life compared to standard steel blades.

Yes, the blades can be resharpened multiple times (usually 2–3 times) before replacement is needed. Yafei recommends professional sharpening to maintain the blades’ original shape and performance—improper sharpening can reduce efficiency or cause premature wear.

Yafei offers blades for most standard twin-shaft shredder brands and models. Provide your shredder’s make, model, and shaft dimensions, and the team will confirm compatibility or design custom blades to fit.