- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

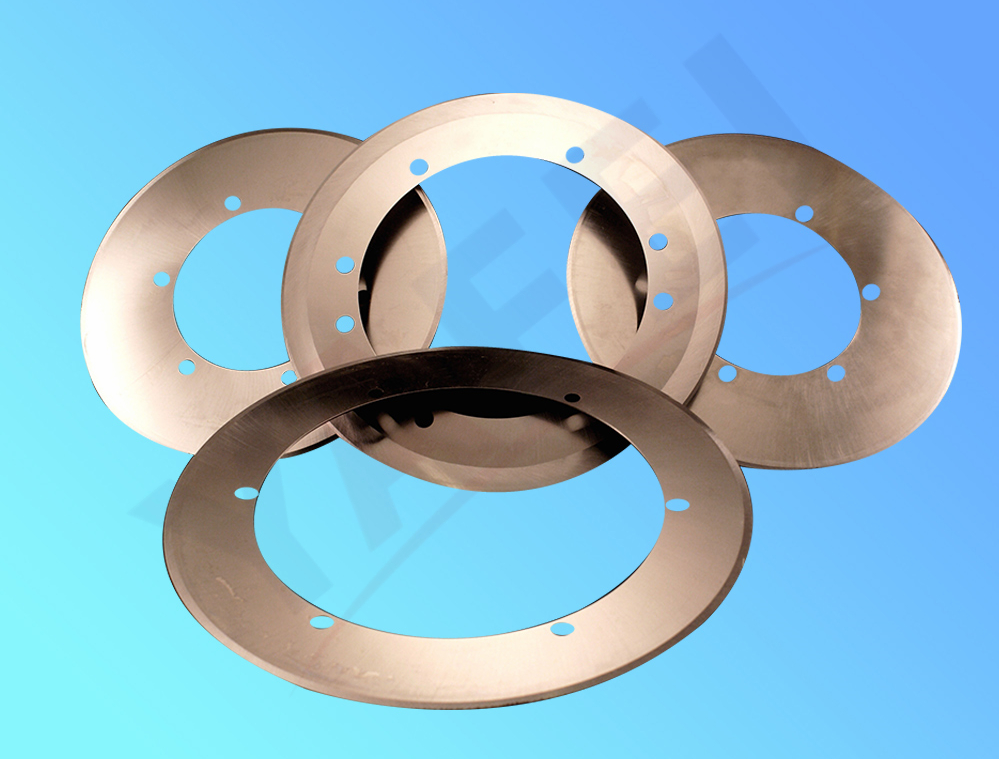

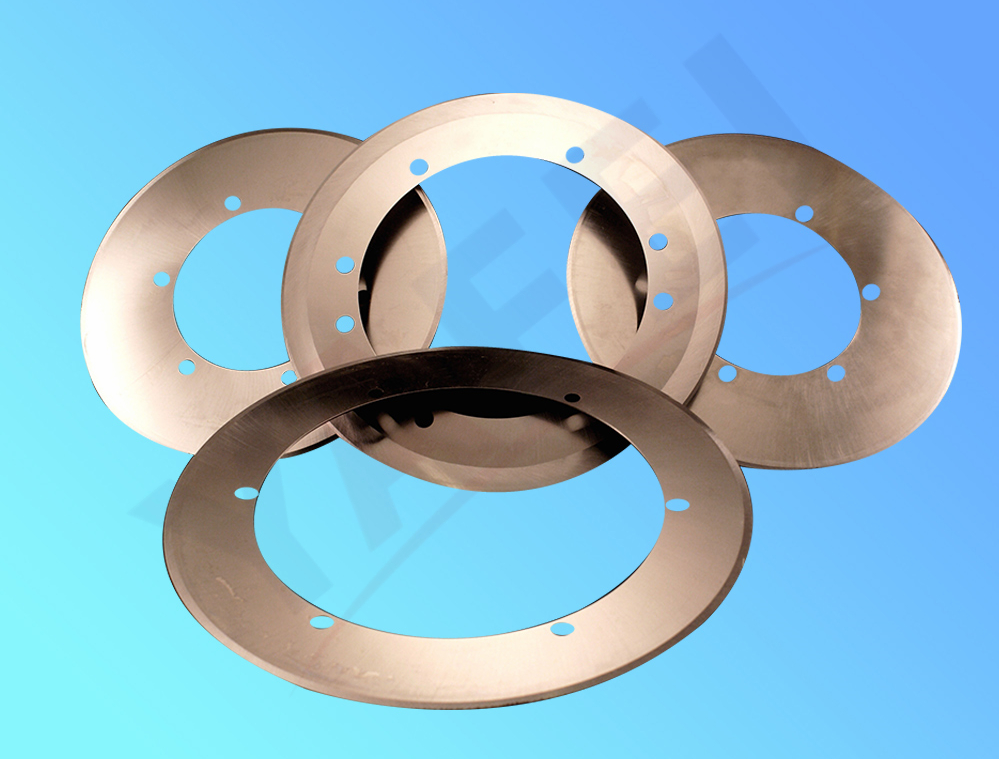

Custom Paper Cardboard Cross-Cutting Blades are precision-engineered cutting tools designed exclusively for the paper and cardboard processing industries. Unlike standard off-the-shelf blades, these products are tailored to meet the unique needs of different production lines—whether you’re cutting pulp, plain paper, thick cardboard, corrugated cardboard, or even lightweight tissue materials.

Our cross-cutting blades integrate with key paper industry machines, including sheeters, slitters, cut-off machines, and cross-cutting equipment, ensuring seamless compatibility with workflows ranging from small-scale paper processing to large-volume corrugated box manufacturing. We prioritize dimensional accuracy, offering customizations based on critical parameters like outside diameter (OD), inner diameter (ID), thickness (T), number of holes, and hole diameter—for example, crafting blades like ø220×ø115×1.0 mm for Agnati machines or ø240×ø32×1.2 mm for BHS slitters. This flexibility ensures every blade aligns perfectly with your existing equipment, eliminating downtime from ill-fitting tools and boosting overall productivity.

Our Custom Paper Cardboard Cross-Cutting Blades are primarily crafted from high-grade carbide, a material renowned for its exceptional wear resistance and hardness. Compared to ordinary steel blades, carbide blades maintain sharp cutting edges up to 5x longer, even when cutting abrasive materials like corrugated cardboard or thick pulp. This durability reduces the frequency of blade replacements, lowering maintenance costs and minimizing production interruptions. For specific light-duty needs (e.g., tissue cutting), we also offer specialized steel alloys treated for enhanced sharpness and corrosion resistance.

No two paper production lines are identical—and neither should your blades be. We offer end-to-end customization, including:

Dimensional adjustments: Match OD (from 220mm to 340mm+), ID, and thickness (0.8mm to 2.0mm+) to your machine’s specifications.

Tooth design: Choose serrated blades for grip during thick cardboard cutting or plain (toothless) blades for smooth, clean cuts on thin paper/tissue.

Hole customization: Adjust number of holes (3 to 8+) and hole diameter (7.6mm to 12.0mm) for easy installation on knife holders.

This level of personalization ensures your blades work in harmony with machines from leading brands like Fosber, Gopfert, Isowa, and Mitsubishi.

Accuracy is critical in paper processing—even a 0.1mm deviation can lead to wasted materials. Our cross-cutting blades are ground using advanced CBN (cubic boron nitride) grinding wheels (as referenced in our tissue industry solutions) to achieve ultra-fine cutting edges. This precision ensures consistent cut lengths, reduces paper/cardboard waste by up to 15%, and improves the quality of finished products (e.g., neatly cut corrugated boxes or evenly sized tissue sheets).

We’ve engineered our custom blades to fit over 20 leading paper industry machine brands, including:

Agnati, BHS, and Fosber (sheeters/slitters)

Gopfert, Isowa, and Marquip (corrugated cardboard equipment)

Mitsubishi and Peters (paper processing machines)

This compatibility eliminates the need for costly machine modifications, making our blades a plug-and-play solution for most production lines.

In the packaging sector, these blades are widely used for cutting corrugated cardboard into box blanks, inserts, or protective packaging materials. Their custom design allows them to adapt to different box sizes and styles, from small retail packages to large shipping boxes, supporting diverse packaging needs.

For printing companies handling paper-based products like catalogs, brochures, or book covers, the blades ensure precise cutting of printed sheets into final sizes. The clean cuts preserve the integrity of printed graphics, avoiding smudging or tearing that could ruin the finished product.

E-commerce businesses and warehouses that process large volumes of cardboard for shipping often rely on these blades to cut packaging materials to fit specific product dimensions. This customization helps reduce packaging waste and ensures products are securely wrapped, lowering the risk of damage during transit.

Yes—we support customization for over 20 leading machine brands (Agnati, BHS, Fosber, etc.). To ensure a perfect fit, simply share your machine’s model number and key parameters (e.g., required blade OD/ID/thickness), and our team will design a blade that aligns with your equipment’s specifications.

The lifespan depends on usage frequency and the material being cut:

For corrugated cardboard (abrasive): 3–6 months of daily use.

For plain paper/tissue (non-abrasive): 6–12 months of daily use.

Regular maintenance (e.g., cleaning and occasional sharpening with CBN grinding wheels) can extend lifespan by an additional 20–30%.

Absolutely—we offer combined customizations to meet unique needs. For example, if you need a serrated blade for thick cardboard cutting and 6 holes (9.0mm diameter) for installation on a Fosber machine, we can design and manufacture that exact blade.

Standard custom orders (e.g., adjusting OD/ID/thickness for common machine brands) have a lead time of 5–7 business days. For highly specialized designs (e.g., unique tooth patterns or large-scale orders of 100+ blades), lead time may extend to 10–12 business days. Rush orders are available upon request for an additional fee.

Yes—every order includes a maintenance guide with tips like:

Cleaning blades with a non-abrasive cloth after use to remove paper dust.

Using CBN grinding wheels (not ordinary grinders) for sharpening to preserve carbide edges.

Replacing blades immediately if you notice uneven cuts or dull edges (to avoid machine damage).

Custom Paper Cardboard Cross-Cutting Blades are precision-engineered cutting tools designed exclusively for the paper and cardboard processing industries. Unlike standard off-the-shelf blades, these products are tailored to meet the unique needs of different production lines—whether you’re cutting pulp, plain paper, thick cardboard, corrugated cardboard, or even lightweight tissue materials.

Our cross-cutting blades integrate with key paper industry machines, including sheeters, slitters, cut-off machines, and cross-cutting equipment, ensuring seamless compatibility with workflows ranging from small-scale paper processing to large-volume corrugated box manufacturing. We prioritize dimensional accuracy, offering customizations based on critical parameters like outside diameter (OD), inner diameter (ID), thickness (T), number of holes, and hole diameter—for example, crafting blades like ø220×ø115×1.0 mm for Agnati machines or ø240×ø32×1.2 mm for BHS slitters. This flexibility ensures every blade aligns perfectly with your existing equipment, eliminating downtime from ill-fitting tools and boosting overall productivity.

Our Custom Paper Cardboard Cross-Cutting Blades are primarily crafted from high-grade carbide, a material renowned for its exceptional wear resistance and hardness. Compared to ordinary steel blades, carbide blades maintain sharp cutting edges up to 5x longer, even when cutting abrasive materials like corrugated cardboard or thick pulp. This durability reduces the frequency of blade replacements, lowering maintenance costs and minimizing production interruptions. For specific light-duty needs (e.g., tissue cutting), we also offer specialized steel alloys treated for enhanced sharpness and corrosion resistance.

No two paper production lines are identical—and neither should your blades be. We offer end-to-end customization, including:

Dimensional adjustments: Match OD (from 220mm to 340mm+), ID, and thickness (0.8mm to 2.0mm+) to your machine’s specifications.

Tooth design: Choose serrated blades for grip during thick cardboard cutting or plain (toothless) blades for smooth, clean cuts on thin paper/tissue.

Hole customization: Adjust number of holes (3 to 8+) and hole diameter (7.6mm to 12.0mm) for easy installation on knife holders.

This level of personalization ensures your blades work in harmony with machines from leading brands like Fosber, Gopfert, Isowa, and Mitsubishi.

Accuracy is critical in paper processing—even a 0.1mm deviation can lead to wasted materials. Our cross-cutting blades are ground using advanced CBN (cubic boron nitride) grinding wheels (as referenced in our tissue industry solutions) to achieve ultra-fine cutting edges. This precision ensures consistent cut lengths, reduces paper/cardboard waste by up to 15%, and improves the quality of finished products (e.g., neatly cut corrugated boxes or evenly sized tissue sheets).

We’ve engineered our custom blades to fit over 20 leading paper industry machine brands, including:

Agnati, BHS, and Fosber (sheeters/slitters)

Gopfert, Isowa, and Marquip (corrugated cardboard equipment)

Mitsubishi and Peters (paper processing machines)

This compatibility eliminates the need for costly machine modifications, making our blades a plug-and-play solution for most production lines.

In the packaging sector, these blades are widely used for cutting corrugated cardboard into box blanks, inserts, or protective packaging materials. Their custom design allows them to adapt to different box sizes and styles, from small retail packages to large shipping boxes, supporting diverse packaging needs.

For printing companies handling paper-based products like catalogs, brochures, or book covers, the blades ensure precise cutting of printed sheets into final sizes. The clean cuts preserve the integrity of printed graphics, avoiding smudging or tearing that could ruin the finished product.

E-commerce businesses and warehouses that process large volumes of cardboard for shipping often rely on these blades to cut packaging materials to fit specific product dimensions. This customization helps reduce packaging waste and ensures products are securely wrapped, lowering the risk of damage during transit.

Yes—we support customization for over 20 leading machine brands (Agnati, BHS, Fosber, etc.). To ensure a perfect fit, simply share your machine’s model number and key parameters (e.g., required blade OD/ID/thickness), and our team will design a blade that aligns with your equipment’s specifications.

The lifespan depends on usage frequency and the material being cut:

For corrugated cardboard (abrasive): 3–6 months of daily use.

For plain paper/tissue (non-abrasive): 6–12 months of daily use.

Regular maintenance (e.g., cleaning and occasional sharpening with CBN grinding wheels) can extend lifespan by an additional 20–30%.

Absolutely—we offer combined customizations to meet unique needs. For example, if you need a serrated blade for thick cardboard cutting and 6 holes (9.0mm diameter) for installation on a Fosber machine, we can design and manufacture that exact blade.

Standard custom orders (e.g., adjusting OD/ID/thickness for common machine brands) have a lead time of 5–7 business days. For highly specialized designs (e.g., unique tooth patterns or large-scale orders of 100+ blades), lead time may extend to 10–12 business days. Rush orders are available upon request for an additional fee.

Yes—every order includes a maintenance guide with tips like:

Cleaning blades with a non-abrasive cloth after use to remove paper dust.

Using CBN grinding wheels (not ordinary grinders) for sharpening to preserve carbide edges.

Replacing blades immediately if you notice uneven cuts or dull edges (to avoid machine damage).