- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

We supply standard and custom designs. Our product range for the corrugated cardboard industry includes.

Including but not limited: carbide slitting knife, Cross Cutting knife, Circular Knives and Straight Knives with and without teeth, grind wheel, etc.

| Availability: | |

|---|---|

| Quantity: | |

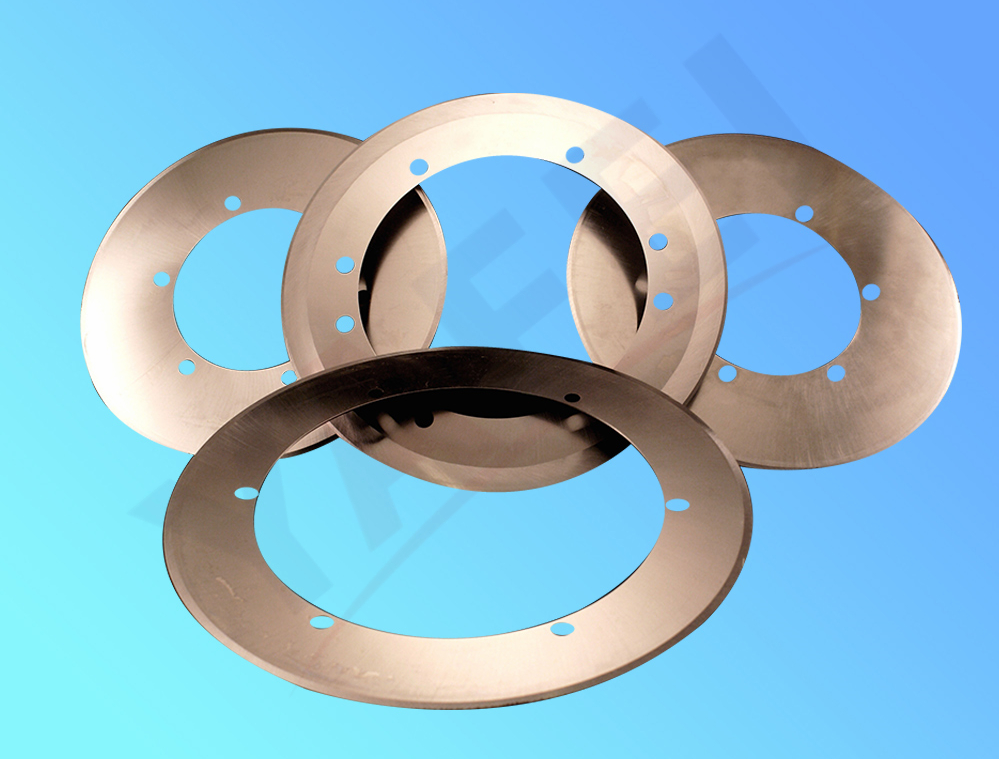

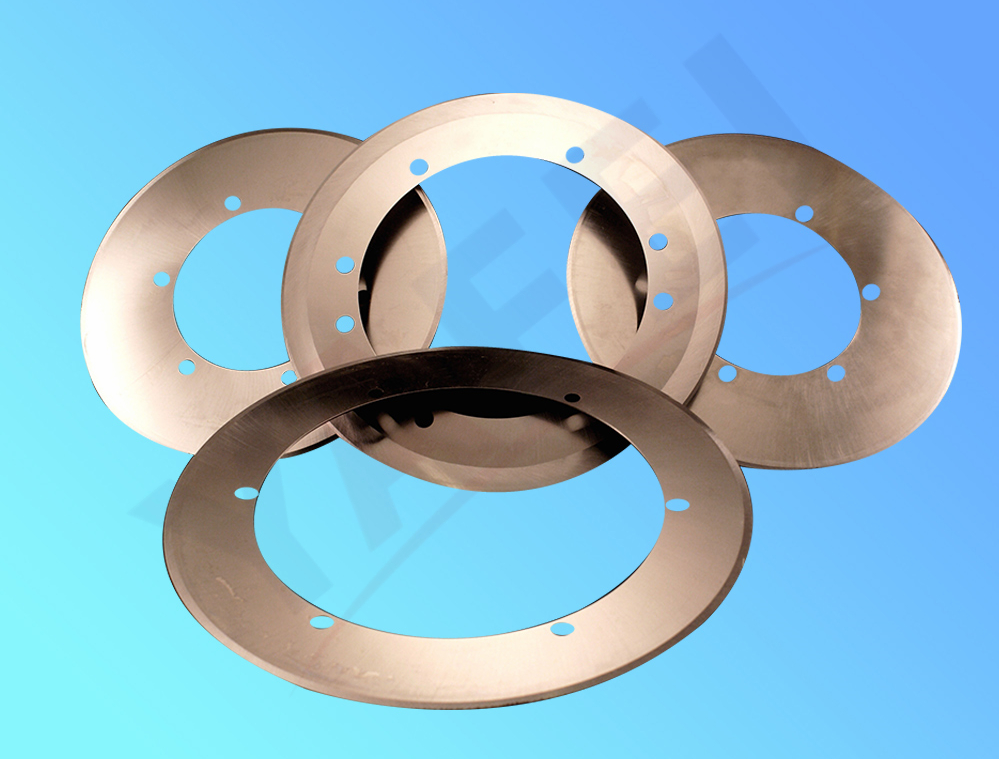

ANHUI YAFEI is a trusted manufacturer of Corrugated Cardboard Circular Slitting Knives—specialized tools designed to meet the unique challenges of cutting corrugated cardboard in packaging and manufacturing industries. Corrugated cardboard is known for its layered structure, which requires sharp, durable blades to ensure clean cuts without crushing or damaging the material. Our circular slitting knives are engineered with precision, featuring advanced coatings and high-quality materials to deliver consistent performance in high-volume cardboard processing. Whether you’re producing shipping boxes, product packaging, or display materials, our Corrugated Cardboard Circular Slitting Knives help streamline your production line and improve the quality of your final products.

Many of our Corrugated Cardboard Circular Slitting Knives are equipped with the proprietary Duriks-41 coating, which provides exceptional wear resistance and reduces friction between the blade and cardboard. This coating prevents the blade from accumulating cardboard dust and fibers, minimizing the need for frequent cleaning and maintaining sharpness for longer. The result is smoother cuts, fewer production interruptions, and an extended blade lifespan—even when processing thick or multi-layered corrugated cardboard.

We offer two primary material options for our circular slitting knives: carbide and high-strength alloys. Carbide knives are ideal for heavy-duty applications, as they are extremely hard and resistant to chipping, making them suitable for cutting thick or rigid corrugated cardboard. Alloy knives, on the other hand, offer a balance of durability and flexibility, making them perfect for medium-volume operations or processing lighter corrugated materials. Both options are heat-treated to enhance their mechanical properties, ensuring reliable performance in continuous use.

Our Corrugated Cardboard Circular Slitting Knives are available in a range of styles to suit different processing requirements, including standard circular knives, serrated knives, and cross-cutting knives. We also provide complementary accessories such as knife holders, grinding wheels, and anvil knives—creating a complete slitting solution that integrates seamlessly with your existing equipment. This versatility means you can handle a variety of tasks, from slitting large cardboard rolls into smaller widths to cutting pre-rolled cardboard into specific lengths for box production.

Every knife is manufactured using advanced CNC machining techniques to ensure exact dimensions and uniform blade edges. This precision guarantees that each cut is straight and clean, avoiding the "ragged" edges that can weaken cardboard packaging or compromise its appearance. The consistent performance of our knives also reduces material waste, as fewer pieces are discarded due to poor cutting quality.

Our Corrugated Cardboard Circular Slitting Knives are essential for businesses involved in corrugated cardboard processing and packaging, including:

• Carton Manufacturing Plants: Producing shipping boxes, storage cartons, and product packaging by slitting and cutting corrugated cardboard rolls.

• E-Commerce Fulfillment Centers: Customizing cardboard sheets into packaging for irregularly shaped items or reinforcing existing packaging for shipping.

• Retail Display Manufacturers: Cutting corrugated cardboard into display stands, shelf organizers, and promotional materials for retail stores.

• Packaging Service Providers: Offering custom packaging solutions to businesses in industries like electronics, food and beverage, and consumer goods.

The Duriks-41 coating serves two key purposes: it reduces friction between the blade and cardboard, which prevents the buildup of dust and fibers, and it enhances the blade’s wear resistance. This means the blade stays sharp longer, requires less cleaning, and can handle higher volumes of cardboard before needing replacement or sharpening.

While our knives are specifically designed for corrugated cardboard, some alloy models can be used for cutting thin paperboard or lightweight packaging materials. However, we do not recommend using them for thick materials like wood or metal, as this can damage the blade edge and reduce its lifespan.

If you process large volumes of thick or rigid corrugated cardboard on a daily basis, carbide knives are the best choice due to their superior durability. If your operation handles lighter cardboard or has lower production volumes, alloy knives offer a more cost-effective option without sacrificing performance. Our team can also assess your specific needs and recommend the right material.

Yes, we offer maintenance guidance, including instructions on sharpening techniques and cleaning procedures. We also supply compatible grinding wheels and other maintenance tools to help you keep your knives in optimal condition. For businesses that prefer professional maintenance, we can arrange for knife sharpening and repair services through our network of partners.

ANHUI YAFEI is a trusted manufacturer of Corrugated Cardboard Circular Slitting Knives—specialized tools designed to meet the unique challenges of cutting corrugated cardboard in packaging and manufacturing industries. Corrugated cardboard is known for its layered structure, which requires sharp, durable blades to ensure clean cuts without crushing or damaging the material. Our circular slitting knives are engineered with precision, featuring advanced coatings and high-quality materials to deliver consistent performance in high-volume cardboard processing. Whether you’re producing shipping boxes, product packaging, or display materials, our Corrugated Cardboard Circular Slitting Knives help streamline your production line and improve the quality of your final products.

Many of our Corrugated Cardboard Circular Slitting Knives are equipped with the proprietary Duriks-41 coating, which provides exceptional wear resistance and reduces friction between the blade and cardboard. This coating prevents the blade from accumulating cardboard dust and fibers, minimizing the need for frequent cleaning and maintaining sharpness for longer. The result is smoother cuts, fewer production interruptions, and an extended blade lifespan—even when processing thick or multi-layered corrugated cardboard.

We offer two primary material options for our circular slitting knives: carbide and high-strength alloys. Carbide knives are ideal for heavy-duty applications, as they are extremely hard and resistant to chipping, making them suitable for cutting thick or rigid corrugated cardboard. Alloy knives, on the other hand, offer a balance of durability and flexibility, making them perfect for medium-volume operations or processing lighter corrugated materials. Both options are heat-treated to enhance their mechanical properties, ensuring reliable performance in continuous use.

Our Corrugated Cardboard Circular Slitting Knives are available in a range of styles to suit different processing requirements, including standard circular knives, serrated knives, and cross-cutting knives. We also provide complementary accessories such as knife holders, grinding wheels, and anvil knives—creating a complete slitting solution that integrates seamlessly with your existing equipment. This versatility means you can handle a variety of tasks, from slitting large cardboard rolls into smaller widths to cutting pre-rolled cardboard into specific lengths for box production.

Every knife is manufactured using advanced CNC machining techniques to ensure exact dimensions and uniform blade edges. This precision guarantees that each cut is straight and clean, avoiding the "ragged" edges that can weaken cardboard packaging or compromise its appearance. The consistent performance of our knives also reduces material waste, as fewer pieces are discarded due to poor cutting quality.

Our Corrugated Cardboard Circular Slitting Knives are essential for businesses involved in corrugated cardboard processing and packaging, including:

• Carton Manufacturing Plants: Producing shipping boxes, storage cartons, and product packaging by slitting and cutting corrugated cardboard rolls.

• E-Commerce Fulfillment Centers: Customizing cardboard sheets into packaging for irregularly shaped items or reinforcing existing packaging for shipping.

• Retail Display Manufacturers: Cutting corrugated cardboard into display stands, shelf organizers, and promotional materials for retail stores.

• Packaging Service Providers: Offering custom packaging solutions to businesses in industries like electronics, food and beverage, and consumer goods.

The Duriks-41 coating serves two key purposes: it reduces friction between the blade and cardboard, which prevents the buildup of dust and fibers, and it enhances the blade’s wear resistance. This means the blade stays sharp longer, requires less cleaning, and can handle higher volumes of cardboard before needing replacement or sharpening.

While our knives are specifically designed for corrugated cardboard, some alloy models can be used for cutting thin paperboard or lightweight packaging materials. However, we do not recommend using them for thick materials like wood or metal, as this can damage the blade edge and reduce its lifespan.

If you process large volumes of thick or rigid corrugated cardboard on a daily basis, carbide knives are the best choice due to their superior durability. If your operation handles lighter cardboard or has lower production volumes, alloy knives offer a more cost-effective option without sacrificing performance. Our team can also assess your specific needs and recommend the right material.

Yes, we offer maintenance guidance, including instructions on sharpening techniques and cleaning procedures. We also supply compatible grinding wheels and other maintenance tools to help you keep your knives in optimal condition. For businesses that prefer professional maintenance, we can arrange for knife sharpening and repair services through our network of partners.