- Home

- Hot

- Products

- Application

- About Us

- Technical Guide

- News

- Contact Us

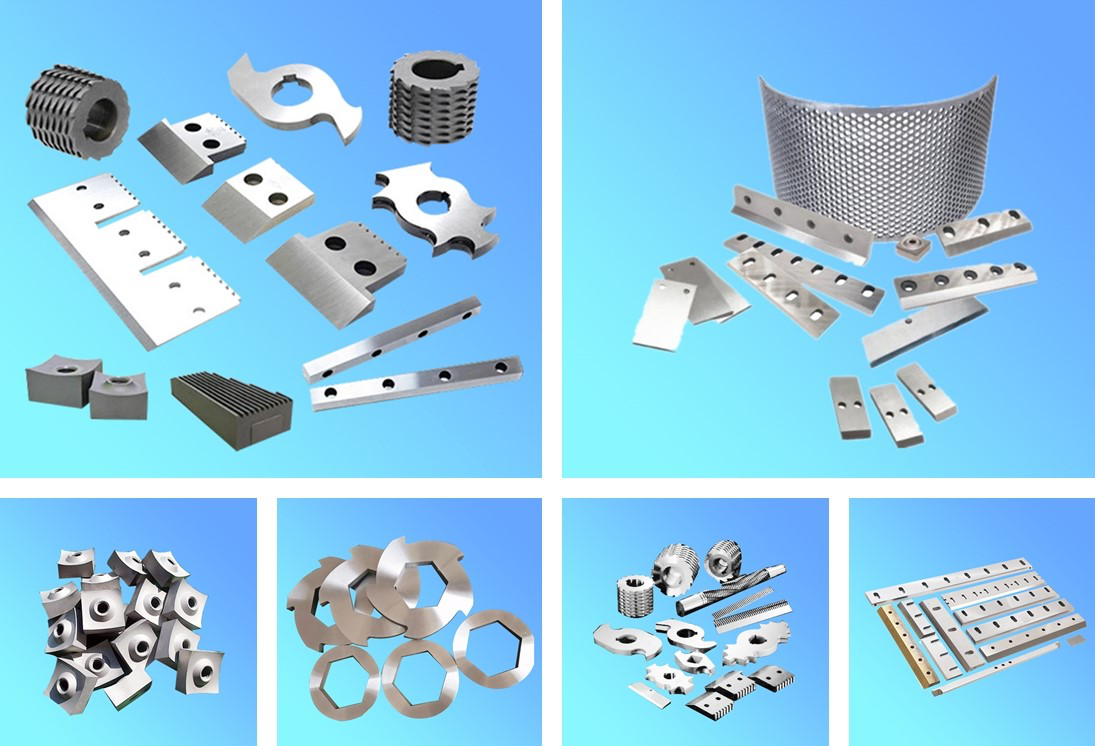

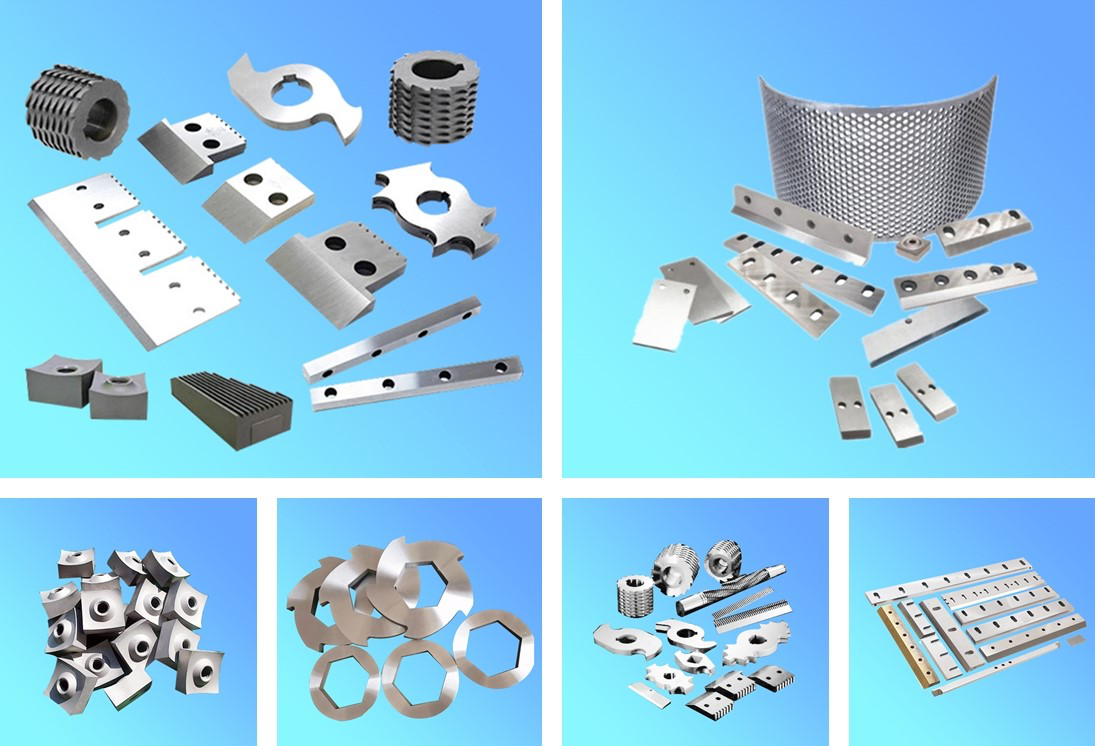

We can customize the blades of various sizes according to your requirements. Our technicians and specialists know all the granulating systems, granulators, cutting mills and recycling plants for the processing of plastics, rubber and recycled products. Shredder knives for shredding and volume reduction of municipal and industrial waste, WEEE, tyres, plastic, paper, cables, aluminum, copper, pulp, biomass, rubber, wood, pallets, medical waste, oil filters, textiles, batteries, etc.

| Availability: | |

|---|---|

| Quantity: | |

Heavy-Duty Plastic Rubber Tyre Crusher Blades are robust cutting tools built to handle the high-stress demands of crushing hard materials like plastic, rubber, and used tyres. Unlike standard crusher blades that may deform or dull quickly when faced with tough, elastic materials, these heavy-duty blades are engineered with strength and resilience in mind. They are a critical component in recycling and waste processing operations, where efficient crushing of plastic waste, rubber scraps, or end-of-life tyres is essential for reducing waste volume and facilitating material reuse. Designed to withstand repeated impact and friction, these blades ensure consistent crushing performance, even in high-volume, continuous-operation environments. Whether used in tyre recycling plants, plastic waste treatment facilities, or rubber manufacturing units, they play a key role in streamlining waste processing workflows and supporting sustainable practices.

Manufactured from high-strength alloy materials, these blades resist wear and damage caused by the hard, abrasive nature of tyres and thick plastic/rubber. The alloy composition is optimized to handle repeated impact— a common challenge when crushing rigid materials—without bending or chipping. This resistance ensures the blades maintain their shape and cutting efficiency over long periods of use.

The blades feature a specialized tooth design and edge geometry that enhances material penetration and fragmentation. When crushing tyres, for example, the design helps break down the tough rubber and steel belts (in some tyre types) into uniform pieces, reducing the need for secondary crushing. For plastic and rubber scraps, the efficient cutting action minimizes material buildup in the crusher, keeping production lines running smoothly.

Crushing hard materials generates friction, which can lead to heat buildup that damages standard blades. These heavy-duty blades are designed to dissipate heat effectively, preventing overheating and maintaining cutting performance even during extended use. This heat resistance also reduces the risk of material melting (a common issue with plastic) that can stick to the blade and disrupt crushing.

In tyre recycling plants, these blades are used to crush end-of-life tyres into smaller pieces (often called “tyre chips”) that can be further processed into rubber granules, used in applications like playground surfaces, road paving, or rubber mats. The blades’ strength allows them to handle the thick rubber and embedded steel components of tyres without damage.

For facilities handling plastic waste—such as discarded plastic containers, industrial plastic scraps, or plastic packaging—these blades crush the material into manageable sizes for recycling. They are effective with various plastic types, including rigid plastics (like PVC or HDPE) and flexible plastics (like LDPE), making them versatile for mixed plastic waste streams.

Rubber manufacturing units often produce scraps during production (e.g., from rubber sheets or moulded products). These blades crush the scraps into reusable rubber pieces that can be reintroduced into the manufacturing process, reducing material waste. They are also used to process old rubber products (like worn-out hoses or gaskets) for recycling.

Yes, these blades are designed to handle tyres with steel belts. The blade’s strength and tooth design allow it to break down the rubber and separate or fragment the steel belts, ensuring efficient crushing without damaging the blade. However, we recommend pairing the blades with crushers that have appropriate separation systems (to remove steel from rubber) for optimal recycling results.

Standard plastic crusher blades are designed for lighter-duty plastic materials and may not withstand the hardness of tyres or thick rubber. Heavy-Duty Plastic Rubber Tyre Crusher Blades have a thicker, more durable build, better impact resistance, and heat dissipation capabilities—features that are critical for crushing tough materials like tyres. Using standard blades for tyre crushing would lead to frequent dulling, deformation, and increased maintenance costs.

Signs that replacement is needed include a noticeable decrease in crushing efficiency (e.g., larger, unevenly crushed pieces), increased noise or vibration from the crusher (indicating the blade is not cutting properly), or visible damage to the blade (like chips, cracks, or significant dullness). Regular inspections (we recommend monthly for high-volume operations) can help identify these signs early and avoid production disruptions.

Heavy-Duty Plastic Rubber Tyre Crusher Blades are robust cutting tools built to handle the high-stress demands of crushing hard materials like plastic, rubber, and used tyres. Unlike standard crusher blades that may deform or dull quickly when faced with tough, elastic materials, these heavy-duty blades are engineered with strength and resilience in mind. They are a critical component in recycling and waste processing operations, where efficient crushing of plastic waste, rubber scraps, or end-of-life tyres is essential for reducing waste volume and facilitating material reuse. Designed to withstand repeated impact and friction, these blades ensure consistent crushing performance, even in high-volume, continuous-operation environments. Whether used in tyre recycling plants, plastic waste treatment facilities, or rubber manufacturing units, they play a key role in streamlining waste processing workflows and supporting sustainable practices.

Manufactured from high-strength alloy materials, these blades resist wear and damage caused by the hard, abrasive nature of tyres and thick plastic/rubber. The alloy composition is optimized to handle repeated impact— a common challenge when crushing rigid materials—without bending or chipping. This resistance ensures the blades maintain their shape and cutting efficiency over long periods of use.

The blades feature a specialized tooth design and edge geometry that enhances material penetration and fragmentation. When crushing tyres, for example, the design helps break down the tough rubber and steel belts (in some tyre types) into uniform pieces, reducing the need for secondary crushing. For plastic and rubber scraps, the efficient cutting action minimizes material buildup in the crusher, keeping production lines running smoothly.

Crushing hard materials generates friction, which can lead to heat buildup that damages standard blades. These heavy-duty blades are designed to dissipate heat effectively, preventing overheating and maintaining cutting performance even during extended use. This heat resistance also reduces the risk of material melting (a common issue with plastic) that can stick to the blade and disrupt crushing.

In tyre recycling plants, these blades are used to crush end-of-life tyres into smaller pieces (often called “tyre chips”) that can be further processed into rubber granules, used in applications like playground surfaces, road paving, or rubber mats. The blades’ strength allows them to handle the thick rubber and embedded steel components of tyres without damage.

For facilities handling plastic waste—such as discarded plastic containers, industrial plastic scraps, or plastic packaging—these blades crush the material into manageable sizes for recycling. They are effective with various plastic types, including rigid plastics (like PVC or HDPE) and flexible plastics (like LDPE), making them versatile for mixed plastic waste streams.

Rubber manufacturing units often produce scraps during production (e.g., from rubber sheets or moulded products). These blades crush the scraps into reusable rubber pieces that can be reintroduced into the manufacturing process, reducing material waste. They are also used to process old rubber products (like worn-out hoses or gaskets) for recycling.

Yes, these blades are designed to handle tyres with steel belts. The blade’s strength and tooth design allow it to break down the rubber and separate or fragment the steel belts, ensuring efficient crushing without damaging the blade. However, we recommend pairing the blades with crushers that have appropriate separation systems (to remove steel from rubber) for optimal recycling results.

Standard plastic crusher blades are designed for lighter-duty plastic materials and may not withstand the hardness of tyres or thick rubber. Heavy-Duty Plastic Rubber Tyre Crusher Blades have a thicker, more durable build, better impact resistance, and heat dissipation capabilities—features that are critical for crushing tough materials like tyres. Using standard blades for tyre crushing would lead to frequent dulling, deformation, and increased maintenance costs.

Signs that replacement is needed include a noticeable decrease in crushing efficiency (e.g., larger, unevenly crushed pieces), increased noise or vibration from the crusher (indicating the blade is not cutting properly), or visible damage to the blade (like chips, cracks, or significant dullness). Regular inspections (we recommend monthly for high-volume operations) can help identify these signs early and avoid production disruptions.